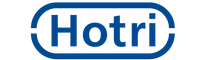

Why Choose Maker Factory's Professional 3D Design and Modeling?

At Maker Factory, you get customized 3D design and modeling that is optimized for both functionality and production. We ensure high precision and quality in every detail, so your project will be a success.

Custom 3D Design Tailored to Your Needs

Whether you have an idea, a sketch or an existing model, we create precise and optimized 3D designs that perfectly fit your project. We work closely with you to ensure the best solution.

From Idea to Finished Product with Precision

We guide you through the entire process from concept to finished model, so you get a well-thought-out design, ready for production. With our experience and advanced tools, we ensure optimal quality and functionality.

Efficient Design, Ready for Production

Our 3D designs are created with a focus on production optimization, so you avoid errors and ensure a smooth production process. We take into account materials, tolerances and printing technology, so your product is ready to be manufactured.

From Idea to Reality – Customized 3D Design

Professional 3D Design, Perfect For Production

Innovation Starts With the Right Design

Turn Your Vision Into a Finished Prototype

When Should You Choose 3D CAD Design? – Precision, Functionality, and Production

3D CAD design is the obvious choice when you need technical precision, production-ready files and functional solutions. CAD (Computer-Aided Design) is used to create detailed and accurate 3D models that can be adapted to production requirements and ensure a smooth manufacturing process.

Choose 3D CAD Design When:

✔ You Must Have a Production-Ready File

CAD designs are optimized for production and can be exported in formats such as STEP, IGES, and STL, which are used for CNC milling, injection molding, and 3D printing.

✔ You Need High Precision And Tolerances

If your project requires exact measurements, technical drawings or specific tolerances, CAD is indispensable. It ensures that all parts fit together and function correctly in a mechanical context.

Typical Uses of 3D CAD Design

Mechanical components and machine parts

Product development and prototypes

Technical drawings and constructions

Industrial production and mass production

3D printing of precise and functional items

With 3D CAD design from Maker Factory, you ensure that your project is ready for production with maximum precision and functionality.

When Should You Choose 3D Modeling? – Creative Shapes, Visual Designs, and Flexibility

3D modeling is the right choice when you need organic shapes, artistic details, and visual presentations. Unlike CAD design, which focuses on precision and production, 3D modeling gives you the freedom to create unique, complex, and aesthetic designs.

Choose 3D Modeling When:

✔ You Should Have An Organic Or Artistic Design

3D modeling is often used for character design, sculptures, and visual concepts, where natural and soft shapes are in focus.

✔ You Work With Games, Animation Or Visual Presentation

If your project requires a high level of detail for rendering, animation or VR/AR, 3D modeling is the best solution.

✔ You Want Unique Products With Decorative Elements

3D modeling allows for freeform design, making it perfect for artistic products, jewelry, sculptures, and custom-designed figures.

✔ You Need High Flexibility In The Design Process

Unlike CAD design, which is often based on technical parameters, 3D modeling allows for rapid changes and experimentation with shapes and details.

Typical Uses of 3D Modeling

- Character design for games, films and animation

- Product visualization and advertising

- Jewelry, artwork and decorative objects

- 3D printing of unique and complex shapes

- VR/AR models and digital experiences

With 3D modeling from Maker Factory, you get the freedom to create unique, detailed, and visually stunning designs, whether for 3D printing, digital rendering, or animation.

Customized 3D Design And Modeling – No Matter Where You Are In Denmark

3D Design throughout Denmark – Professional 3D Modeling and CAD Design

At Maker Factory, we offer custom 3D design and modeling to companies, startups and individuals across Denmark. Whether you need product development, prototypes or technical 3D models, we deliver high-precision CAD designs that are ready for production, 3D printing or CNC milling.

We help customers all over the country – from Copenhagen, Aarhus and Odense to Aalborg and Vejle. Our expertise ensures that you get a functional and production-ready 3D model that matches your needs.

Why Choose Maker Factory For Your 3D Design?

✔ Professional 3D CAD Design – Ready for production and optimized for your industry.

✔ Tailor-made Solutions – From prototypes to mechanical components and custom designs.

✔ Fast Delivery Throughout Denmark – Efficient design process so you can quickly move forward with your project.

✔ Optimized For Production – 3D models that work perfectly for 3D printing, CNC milling, laser cutting, and injection molding.

3D Design in Copenhagen – Precise CAD Design and Customized Modeling

3D Design in Copenhagen – Precise CAD Design and Customized Modeling

Copenhagen is a hub for innovation, and at Maker Factory we provide professional 3D design and advanced CAD modeling to companies, startups, and designers. We create accurate, production-ready 3D models optimized for product development, prototypes, and mechanical components.

Our solutions ensure that your designs are ready for 3D printing, CNC milling or injection molding, regardless of complexity.

Do you need a custom 3D design in Copenhagen? Contact us today!

3D Design in Aarhus – Precision, Product Development and 3D Modeling

3D Design in Aarhus – Precision, Product Development and 3D Modeling

In Aarhus, we collaborate with small and large companies to develop detailed and production-ready 3D models. Our expertise spans industrial design, architecture, medical devices and mechanical components.

We provide customized CAD solutions that ensure your products are optimized for 3D printing, CNC milling and injection molding.

Are you looking for professional 3D design in Aarhus? Contact us today!

3D Design in Odense – CAD Design and Mechanical Components

3D Design in Odense – CAD Design and Mechanical Components

Odense is a growing city in technology and innovation, and we contribute with advanced CAD design, optimization and precise 3D models. We work closely with robotics, machinery and manufacturing companies to create functional and tailored solutions.

Our production-ready 3D designs ensure that your models can be manufactured via 3D printing, CNC milling, or traditional industrial production.

Do you need CAD design in Odense? We are ready to help!

3D Design in Aalborg – Innovation, Details and High Quality

3D Design in Aalborg – Innovation, Details and High Quality

In Aalborg and the rest of North Jutland, we create detailed and optimized 3D models for companies that work with mechanical components, product development and industrial solutions.

Our expertise in 3D CAD and modeling ensures that you get an accurate and functional model that meets production requirements. We focus on high quality, accuracy and design that can be implemented directly into your production.

Do you need professional 3D design in Aalborg? Contact us today!

3D Design in Vejle – Tailor-made 3D Solutions for Production and 3D Printing

3D Design in Vejle – Tailor-made 3D Solutions for Production and 3D Printing

We help companies and entrepreneurs in Vejle create functional and precise 3D designs that match their production technology and manufacturing needs.

Whether you need a prototype, a mechanical component, or a custom-designed product, we deliver optimized 3D models ready for 3D printing, CNC machining, or industrial mass production.

Do you need custom 3D design in Vejle? Contact us today!

3D Design in Esbjerg – Advanced 3D Modeling for Industry and Development

3D Design in Esbjerg – Advanced 3D Modeling for Industry and Development

Esbjerg is a powerhouse for industry, offshore technology and production, and we deliver high-precision 3D design that supports mechanical solutions, product development and custom-made components.

We help industrial companies, engineers and startups alike create production-ready 3D models that can be manufactured via 3D printing, CNC machining or traditional manufacturing methods.

Our experience with CAD design, optimization and simulation ensures that your components are functional, durable and ready for use in even the most demanding environments.

Are you looking for professional 3D design in Esbjerg? Contact us today for a tailor-made solution!

3D Design in Varde – Tailor-made Solutions for Prototypes and Production

3D Design in Varde – Tailor-made Solutions for Prototypes and Production

In Varde, we offer professional 3D design and modeling to companies, entrepreneurs and individuals who need precise and optimized 3D models. Whether you need to develop a prototype, a mechanical component or a custom-designed product, we deliver CAD designs that are perfectly suited for 3D printing, CNC milling or injection molding.

Our expertise covers everything from product development to industrial design, and we ensure that your models are ready for production with high precision.

Do you need 3D design in Varde? Contact us today for a solution that matches your needs.

3D printing opens up endless possibilities!

Inspiration & Applications

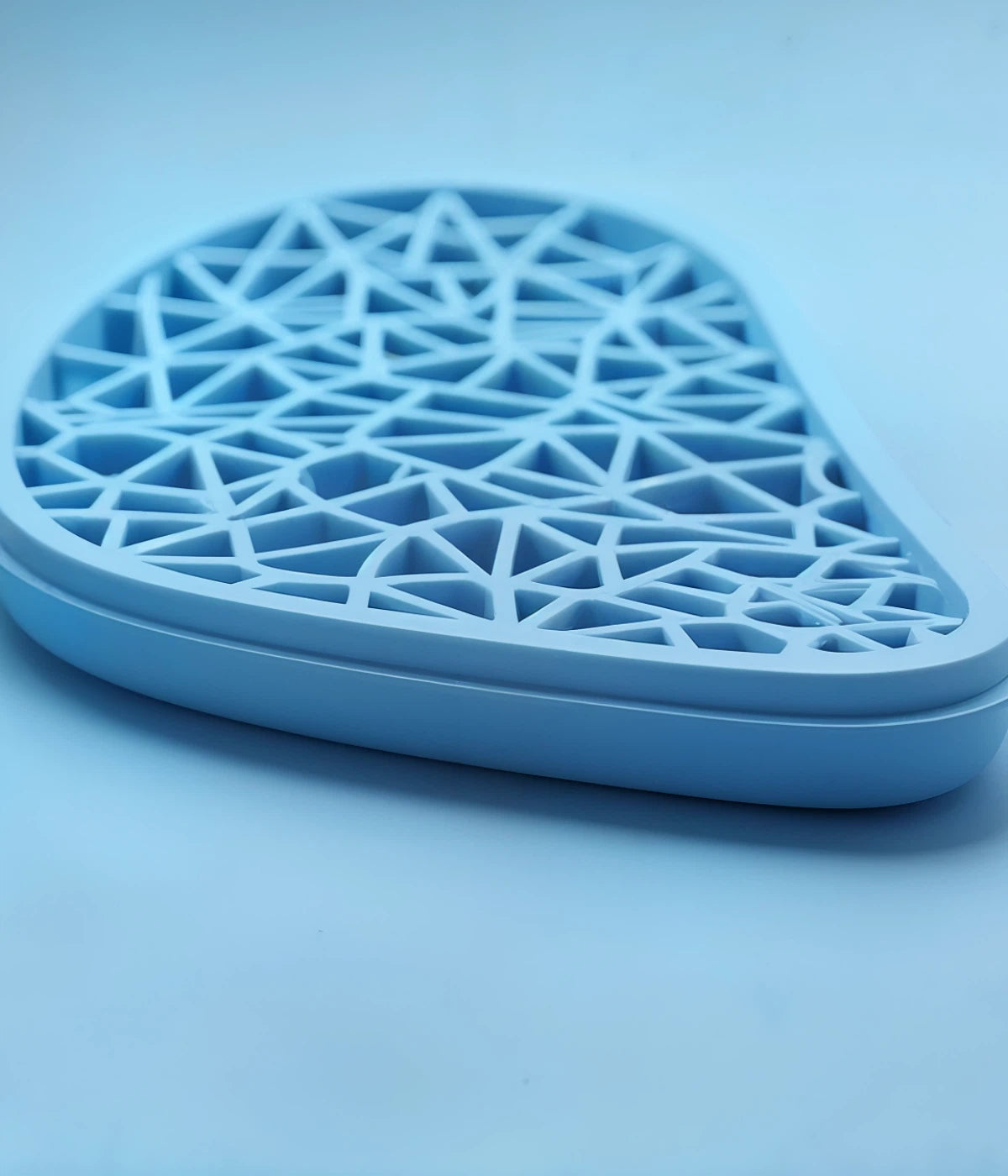

3D design opens up countless possibilities across industries and projects. Whether you're working on product development, prototypes, mechanical components, architecture or artistic projects, 3D modeling can help create precise, functional and innovative solutions.

By using advanced CAD design and 3D modeling, you can develop products faster, reduce costs, and ensure your models are ready for production via 3D printing, CNC milling, or injection molding.

In this section you can find inspiration on how 3D design can optimize your project and give you a competitive advantage in your industry.

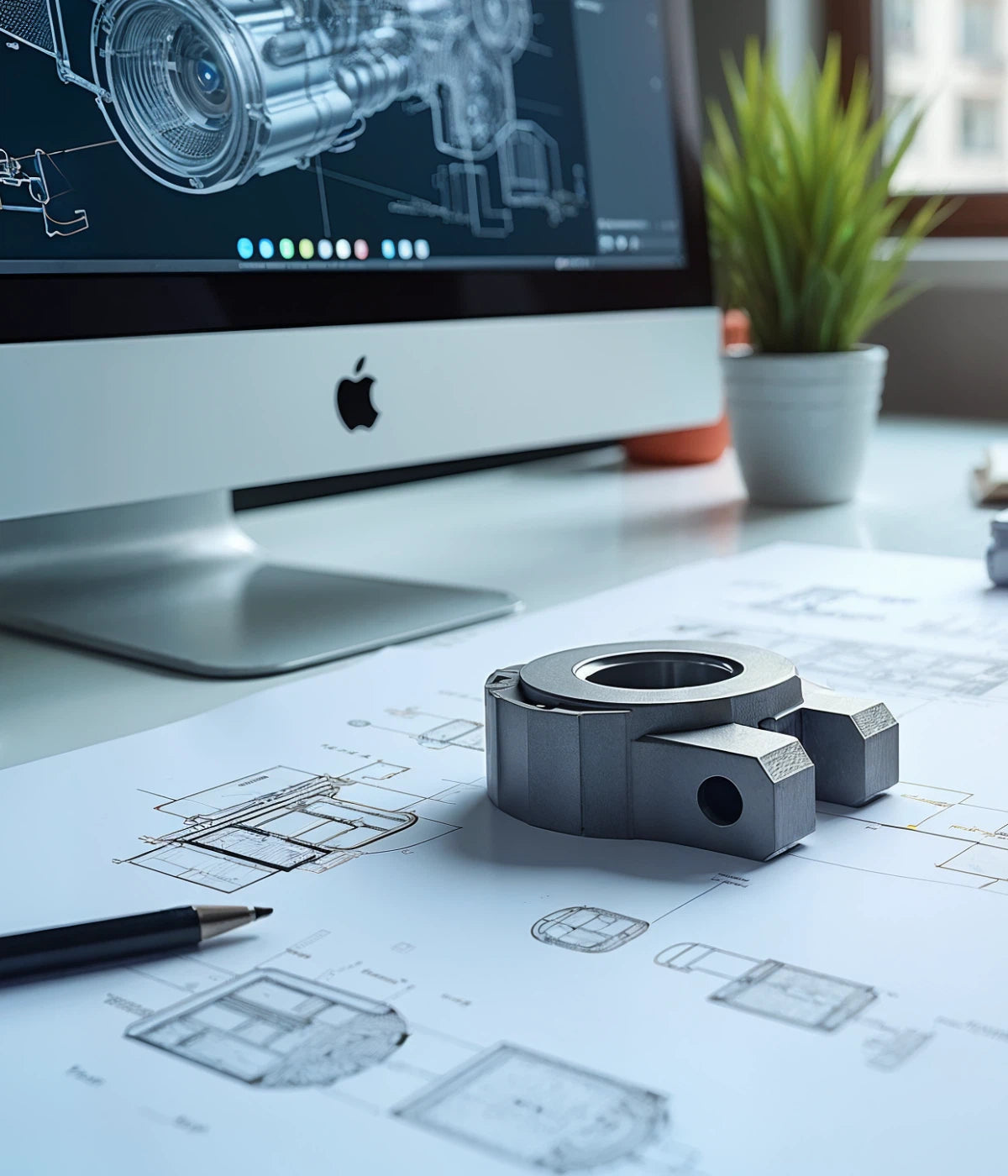

3D Product Development & Prototyping – Rapid Iteration & Optimization

3D Product Development & Prototyping – Rapid Iteration & Optimization

3D design plays a crucial role in product development and prototyping, where rapid iterations are needed to test and refine a product before it is put into production.

Advantages of 3D design in product development:

Faster development process: Digital models can be easily adjusted and tested without the need for physical changes.

Error minimization: With accurate 3D models, you can identify potential problems before production.

Cost efficiency: By optimizing the design digitally, you avoid expensive production changes later.

3D printing capabilities: Rapid production of prototypes that can be physically tested.

Often used for:

Electronics and consumer technology

Industrial design and machine components

Medical and healthcare equipment

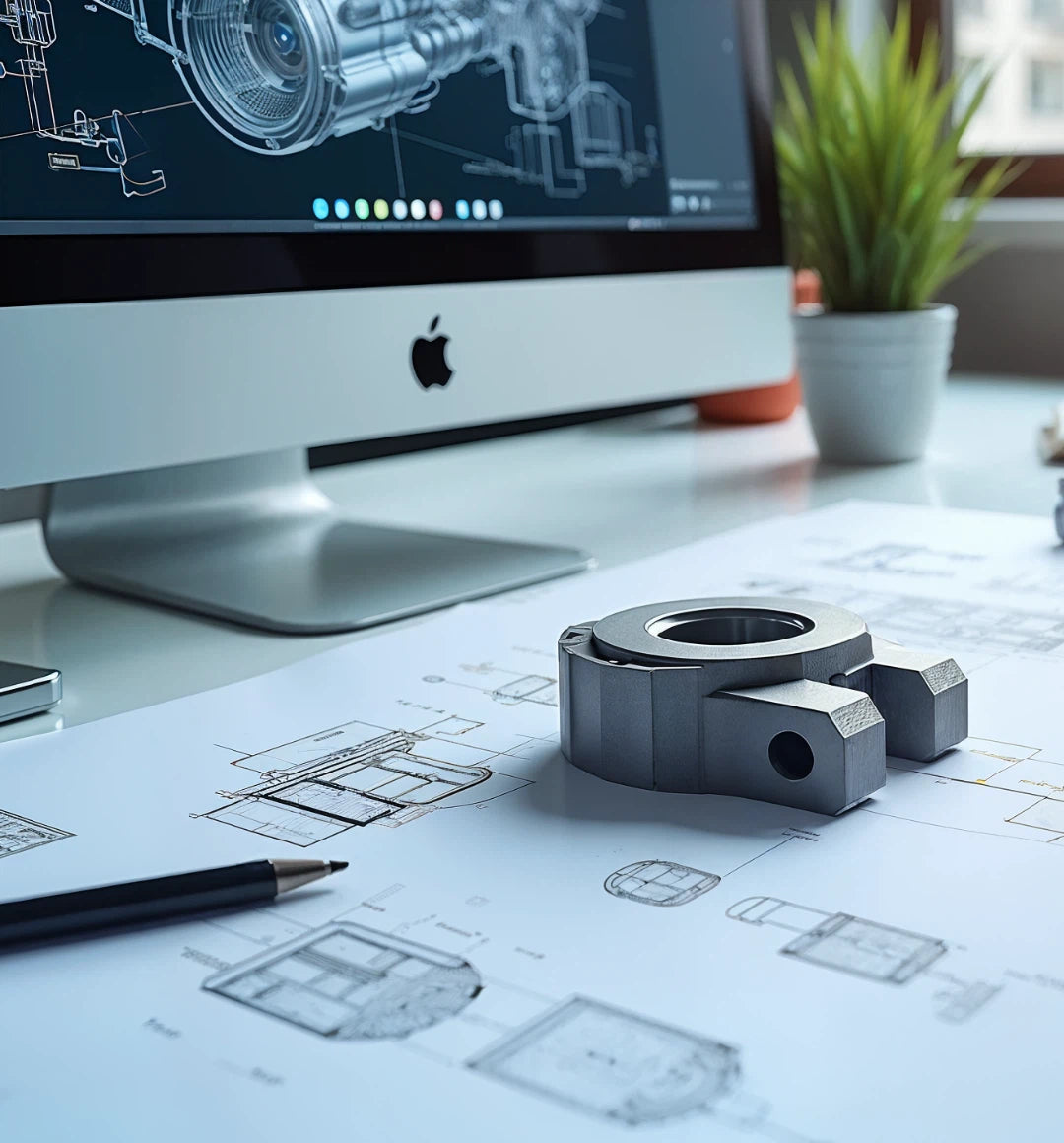

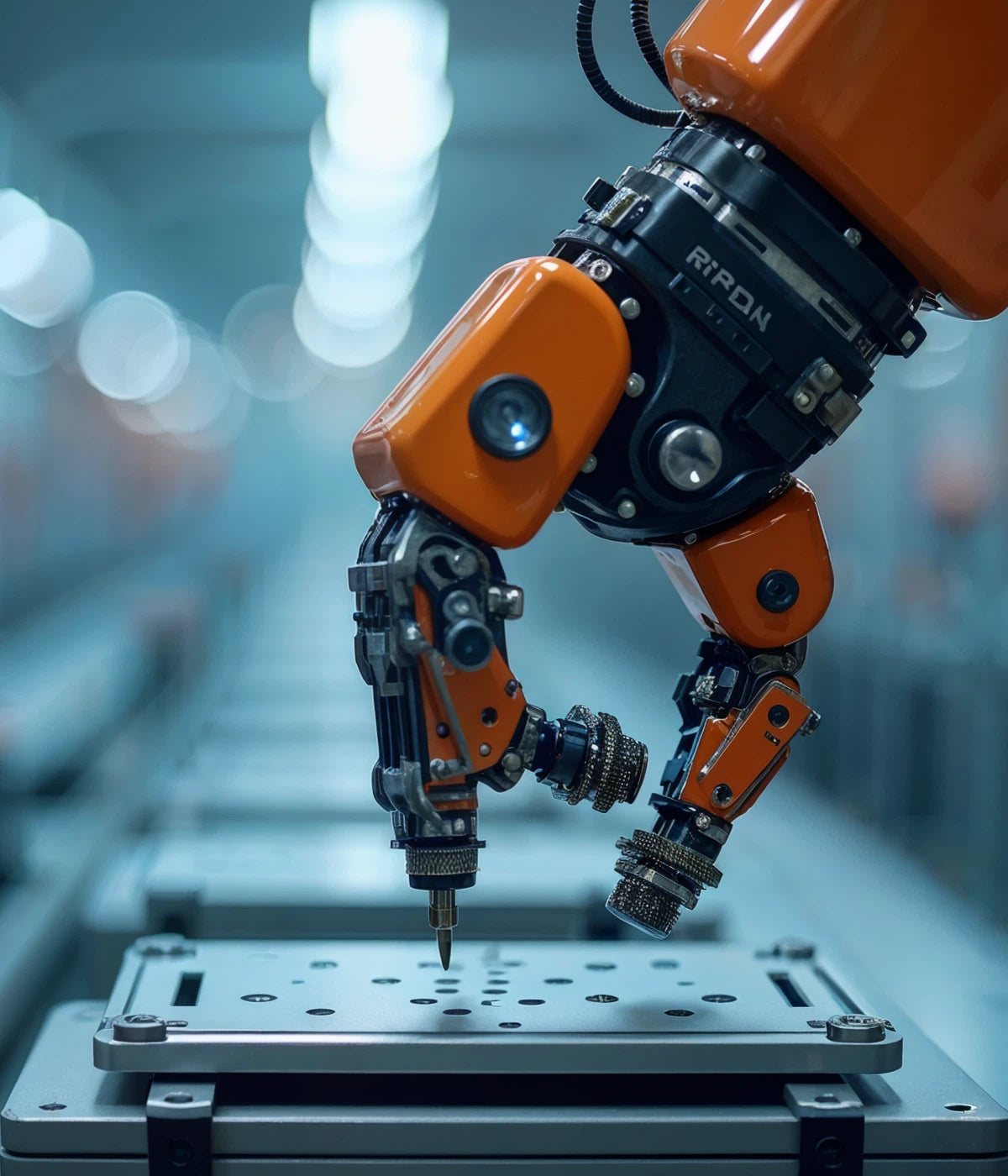

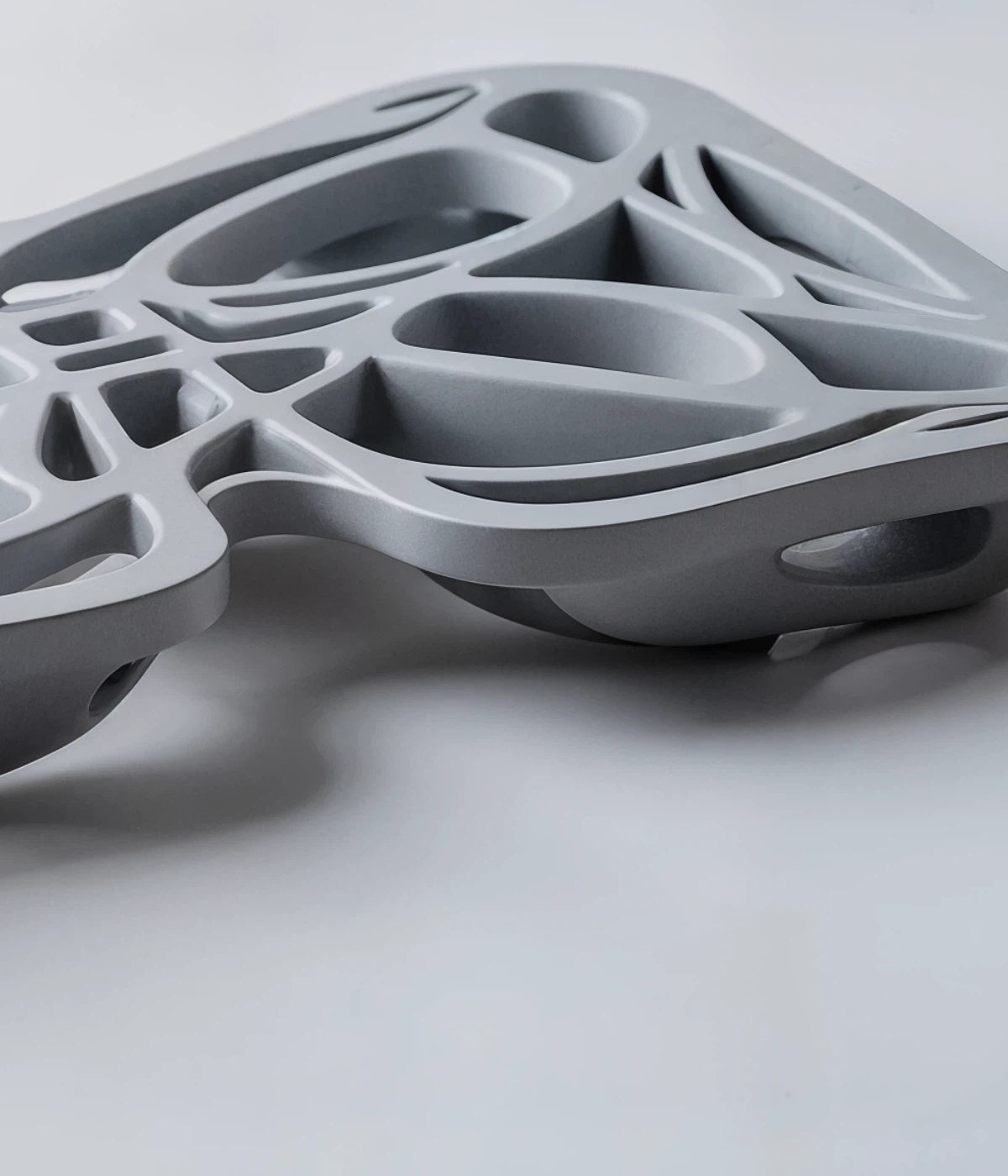

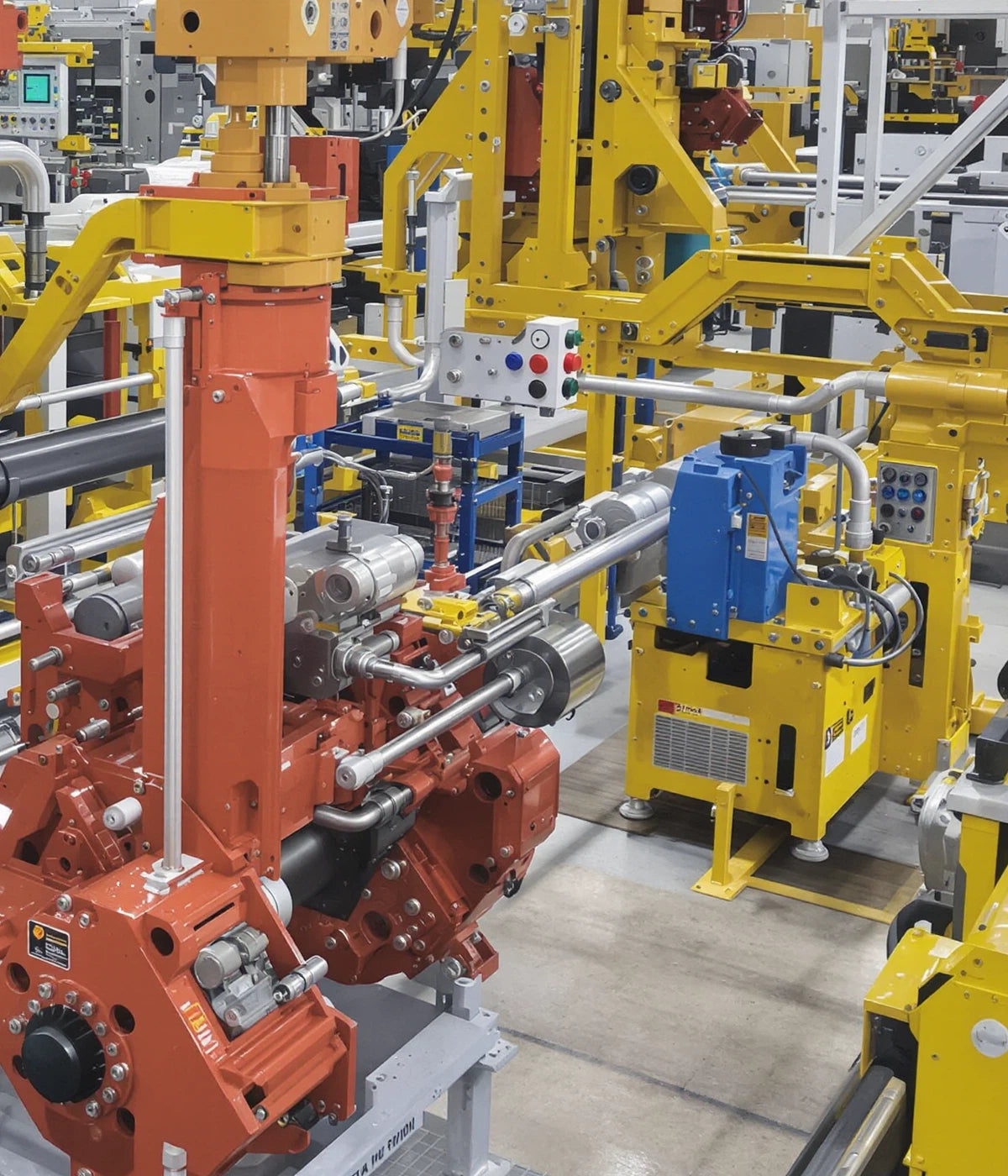

3D Design of Industrial Mechanical Components – Ready for Production

3D Design of Industrial Mechanical Components – Ready for Production

CAD design and 3D modeling are essential in industry, where precision and functionality are crucial for mechanical parts and machine components.

Benefits of 3D modeling for mechanical components:

Precise dimensions and tolerances: Ensures compatibility with existing systems.

Production-ready design: Optimized for CNC milling, injection molding, and metal casting.

Simulation and stress testing: Identify weaknesses and improve durability.

Efficient design change: Easy to adapt components to new requirements.

Often used for:

Production machines and robotics

Aerospace and automotive industry

Custom-made mechanical parts

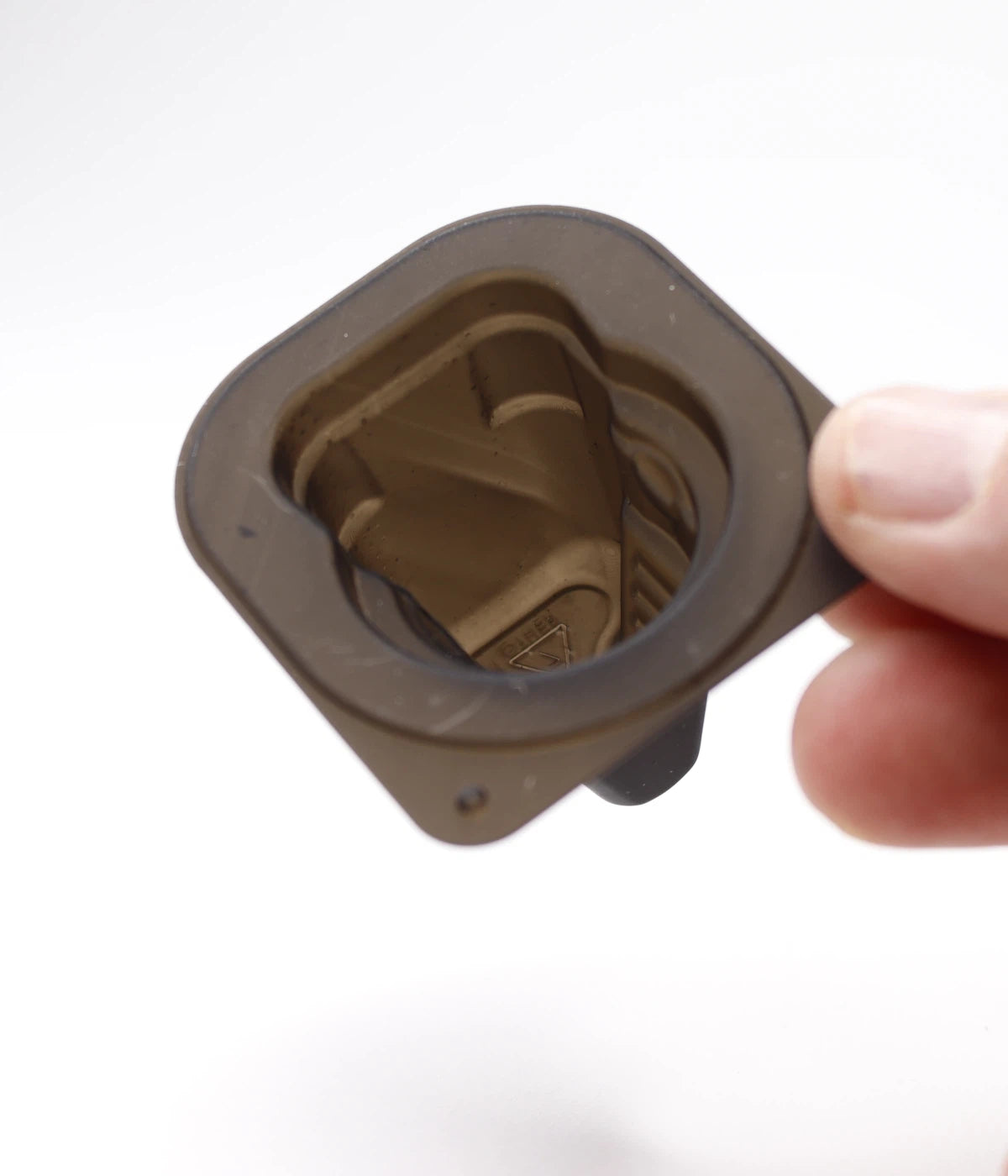

3D Printing, CNC Milling & Production Ready Models

3D Printing, CNC Milling & Production Ready Models

To transition from digital design to physical product, the 3D model must be optimized for the chosen production method.

Benefits of production-ready 3D models:

Error-free design files: Ready for direct production.

Optimized for materials: Ensures maximum durability and performance.

Connection between design and production: Avoid errors in the production phase.

Simulation and testing: Allows for the anticipation of challenges before mass production.

Often used for:

Mass production of components

CNC milled parts for industrial use

3D printed models for rapid manufacturing

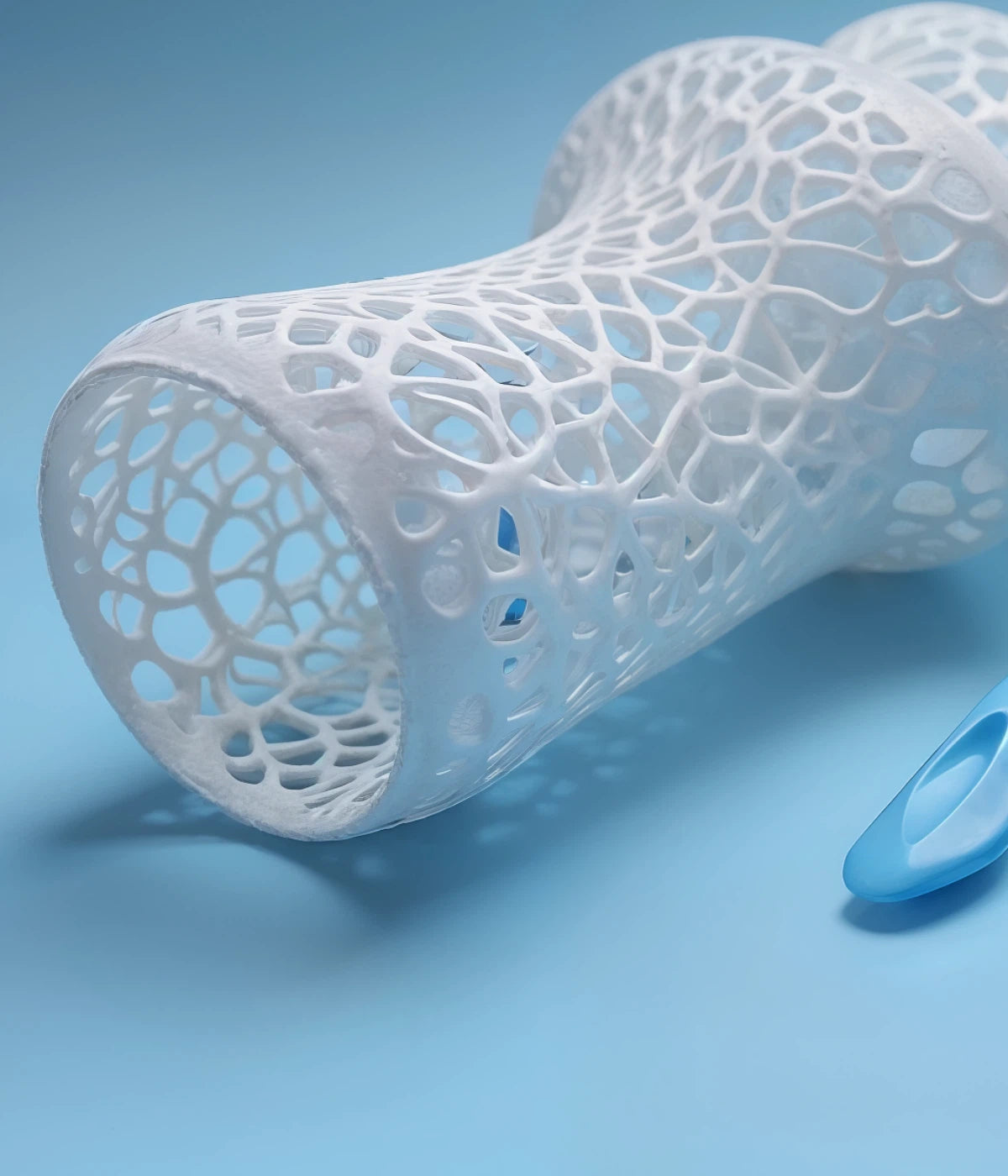

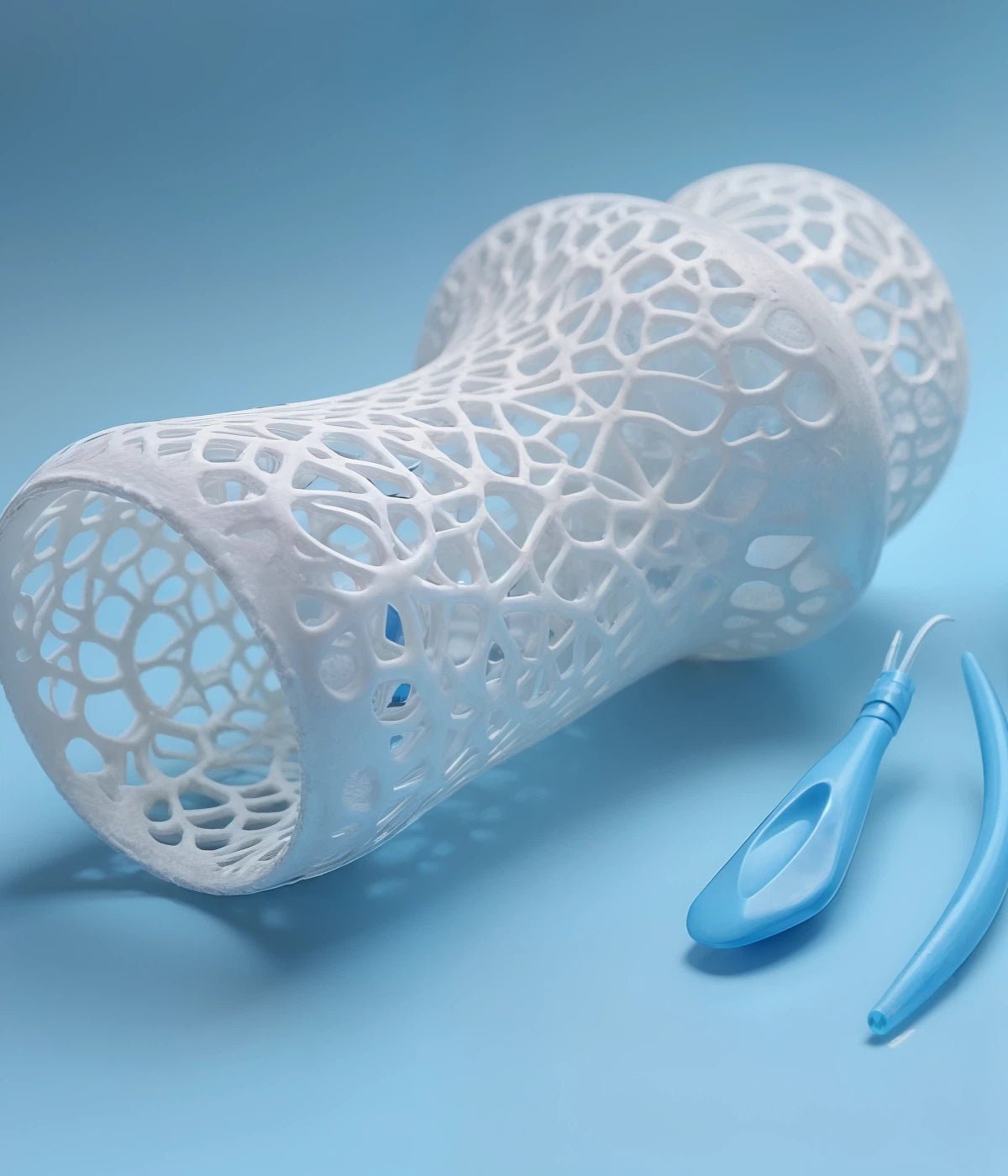

3D Design For Medico & Healthcare Technology – Precision & Customization

3D Design For Medico & Healthcare Technology – Precision & Customization

In the healthcare sector, 3D modeling is used to create patient-specific solutions, such as prosthetics, surgical tools, and medical devices.

Benefits of 3D design in the medical industry:

Individually tailored solutions: 3D modeling enables custom design for the individual patient.

Improved precision in surgery: 3D models can help surgeons with better planning.

Rapid Prototyping: Testing new medical tools and devices.

Integration with bioprinting: Possibility of manufacturing tissue structures and customized implants.

Often used for:

Prostheses and orthopedic aids

Medical research equipment

Customized surgical tools

3D Design For Custom & Artistic Projects

3D Design For Custom & Artistic Projects

3D modeling opens up countless creative possibilities in art, jewelry, sculptures and design.

Benefits of 3D design for art and design:

Unique and complex shapes: Impossible to create with traditional methods.

Optimized for 3D printing: Perfect for custom-designed products and art installations.

Digital creation of physical objects: From digital artworks to sculptures.

Integration with AR/VR: Allows for interactive experiences.

Often used for:

Art installations and sculptures

Jewelry design and the fashion industry

Digital designs for games and animation

3D Modeling for Architecture & Building Design – From Concept to Visualization

3D Modeling for Architecture & Building Design – From Concept to Visualization

Architects and engineers use 3D modeling to create realistic visualizations of buildings, infrastructure, and landscapes.

Advantages of 3D modeling in architecture:

Improved presentation: Realistic 3D models can help convince investors and customers.

Accurate building models: Integration with BIM (Building Information Modeling) systems.

Effective planning: Opportunity to test spatial utilization and design optimization.

Material and lighting simulation: Improves understanding of how the building will look in reality.

Often used for:

Construction and renovation projects

Interior design and home planning

Landscape design and urban development

Get the Right 3D Design Solution for Your Project

Contact Maker Factory – Get Help With Your 3D Design

Are you unsure which 3D design solution is best for your project? At Maker Factory, we advise companies within product development, industry, medicine, robotics, architecture, aviation and many other sectors.

We help you with design optimization, prototypes and production-ready 3D models, so you get an efficient and tailored solution suitable for 3D printing, CNC milling or injection molding.

Contact us today and get professional advice on your 3D design!

From startups to established companies - we create solutions that suit you