What is SLA 3D Printing?

SLA (Stereolithography) is a high-precision 3D printing technology that uses UV-cured resin to create extremely detailed models with a smooth surface.

The technology works by using a UV laser or LCD screen to cure liquid resin layer by layer, resulting in fine detail, high resolution, and minimal post-processing. SLA is ideal for miniatures, technical prototypes, jewelry, medical models, and other advanced applications.

Maker Factory offers professional SLA 3D printing, perfect for visual models, precision parts, and functional prototypes where high levels of detail and a smooth finish are essential.

Find the Perfect SLA Material for Your 3D Print – We'll Advise You!

Introduction to SLA Materials

What Materials Can Be Used With SLA?

SLA 3D printing supports photopolymer resins , each of which has specific properties depending on your application.

At Maker Factory we offer the following SLA materials :

Miniature Resin – Highly Detailed & Perfect For Small Models

Miniature Resin is designed to reproduce even the finest details, making it perfect for miniatures, jewelry, and artistic models.

Advantages:

✔ Extreme sharpness of detail

✔ Smooth finish, ideal for painting & finishing

✔ Low shrinkage, high precision

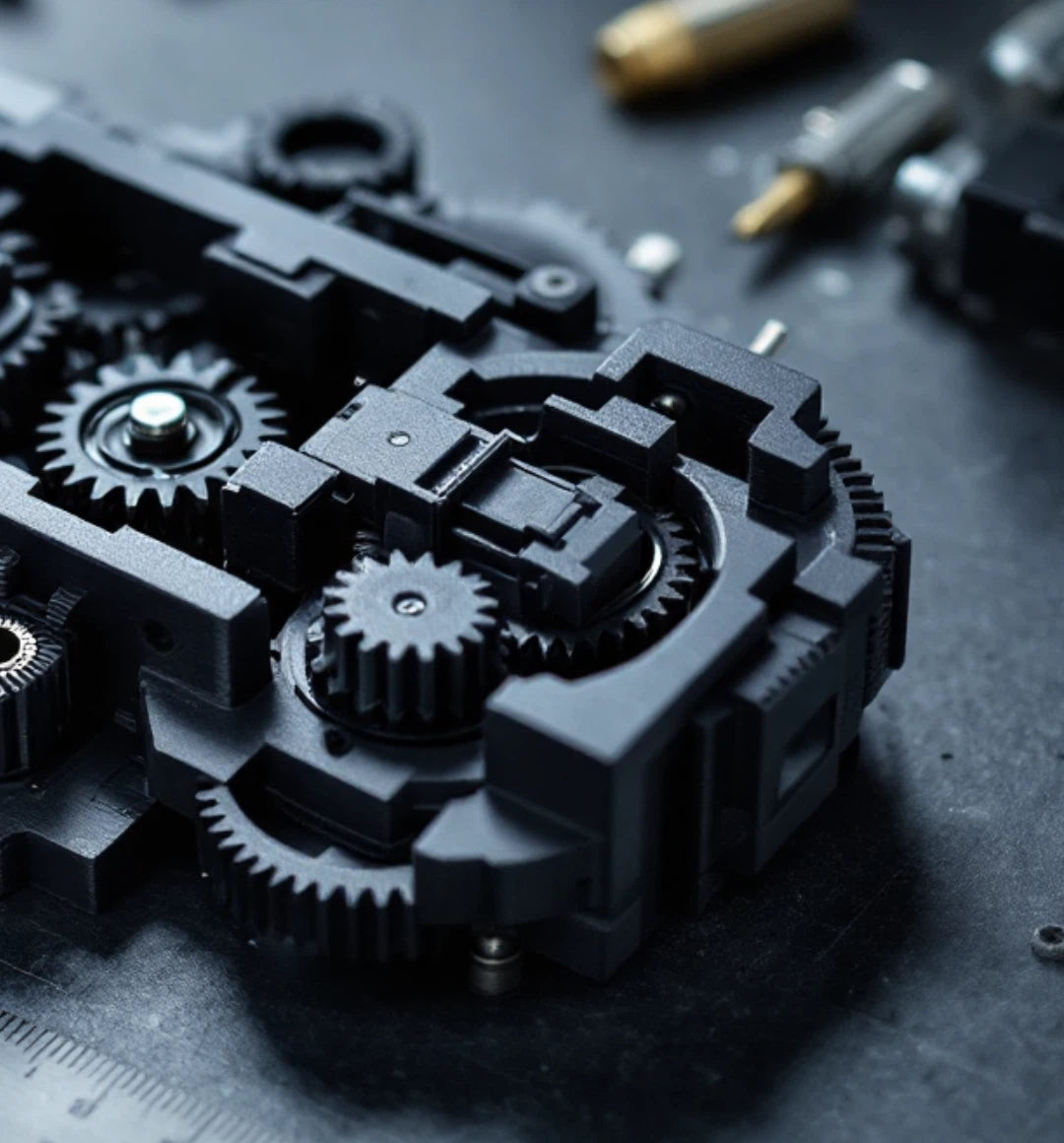

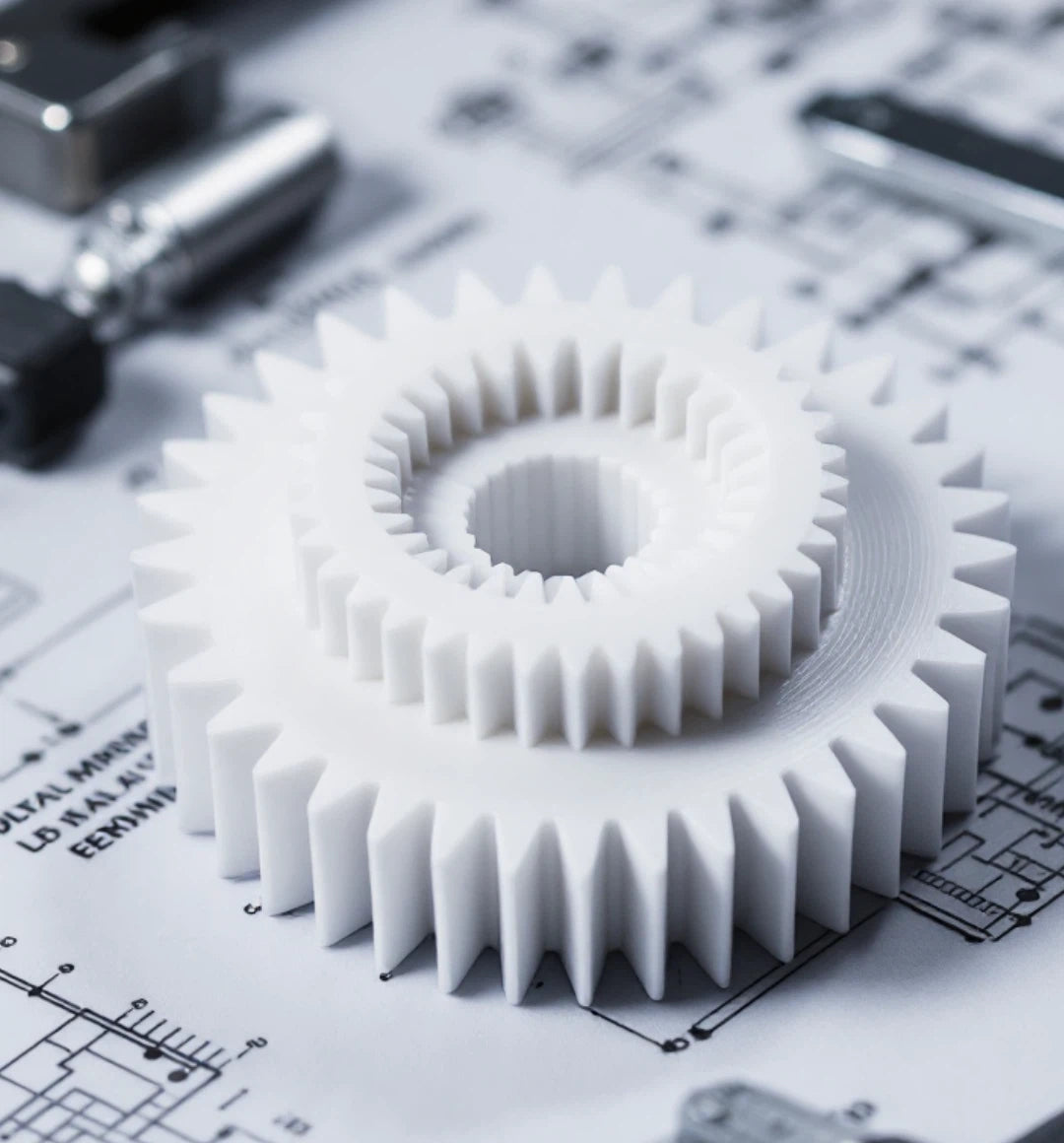

Tough Resin – Impact Resistant & Mechanically Durable

Tough Resin combines high impact strength with flexibility, making it ideal for functional prototypes & mechanical parts.

Advantages:

✔ High impact strength & toughness

✔ Resistant to mechanical stress

✔ Perfect for functional test models

Engineering Resin – High Strength & Technical Precision

Engineering Resin has improved mechanical performance and high temperature resistance , making it perfect for technical prototypes & mechanical components .

Advantages:

✔ High strength & low shrinkage

✔ Chemical resistant & heat resistant

✔ Ideal for engineering & technical test models

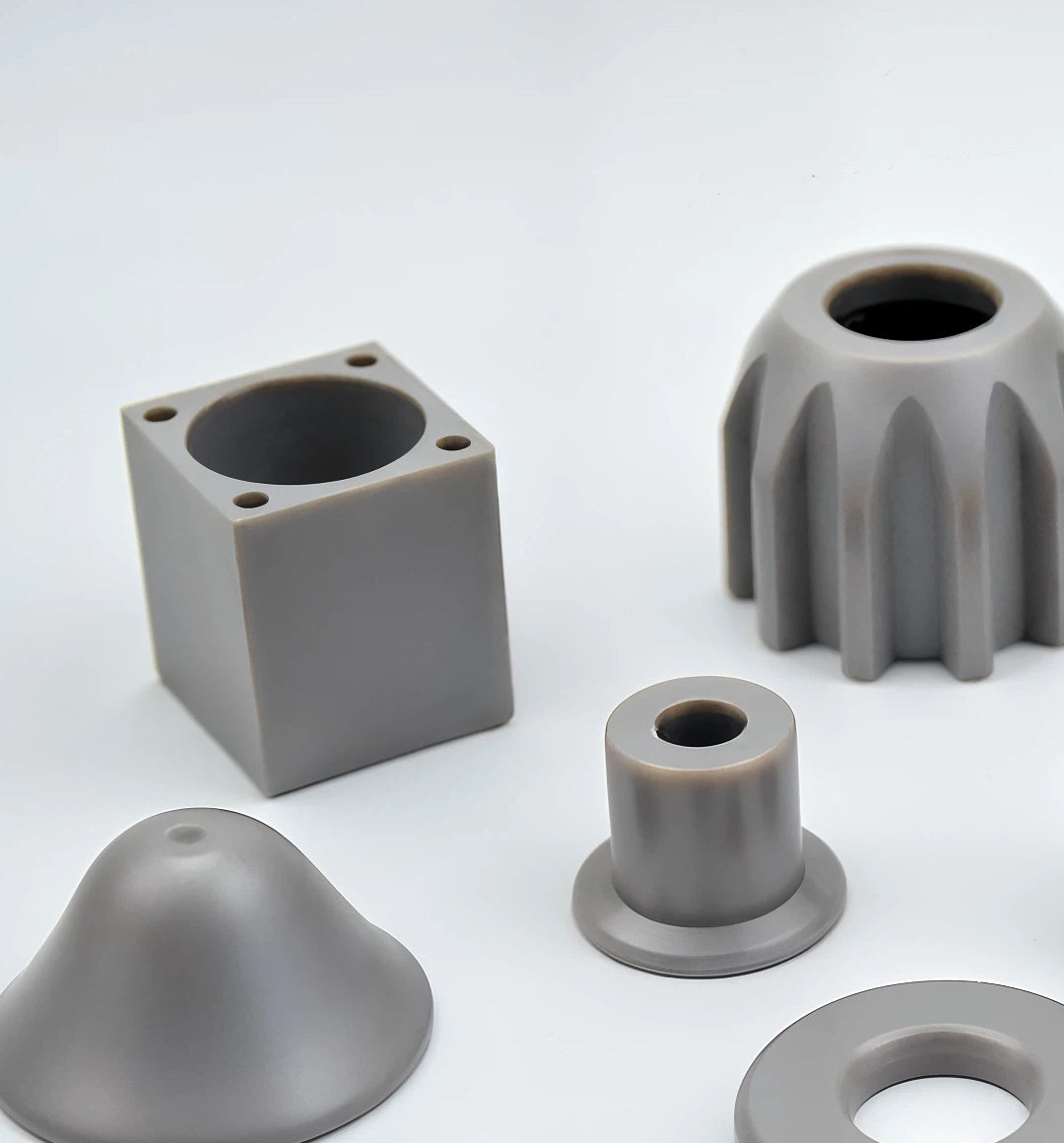

PA-Like Resin – Nylon-Like Flexibility & Abrasion Resistance

PA-Like Resin mimics the properties of nylon , providing a combination of strength & flexibility that is ideal for technical & mechanical components .

Advantages:

✔ High impact strength & toughness

✔ Low shrinkage & high precision

✔ Perfect for functional parts & test models

Flex Resin – Elastic & Shock Absorbing

Flex Resin is an elastic & durable material, perfect for shock absorbers, seals and flexible functional parts.

Advantages:

✔ Soft & elastic

✔ Resistant to repeated loads

✔ Perfect for medical & industrial applications

Ceramic Resin – High Temperature Resistance & Ceramic Finish

Ceramic Resin is a ceramic-like resin that provides a rigid, heat-resistant and smooth surface , perfect for technical components and artistic models .

Advantages:

✔ Smooth, ceramic surface

✔ Withstands high temperatures

✔ Perfect for artistic & industrial purposes

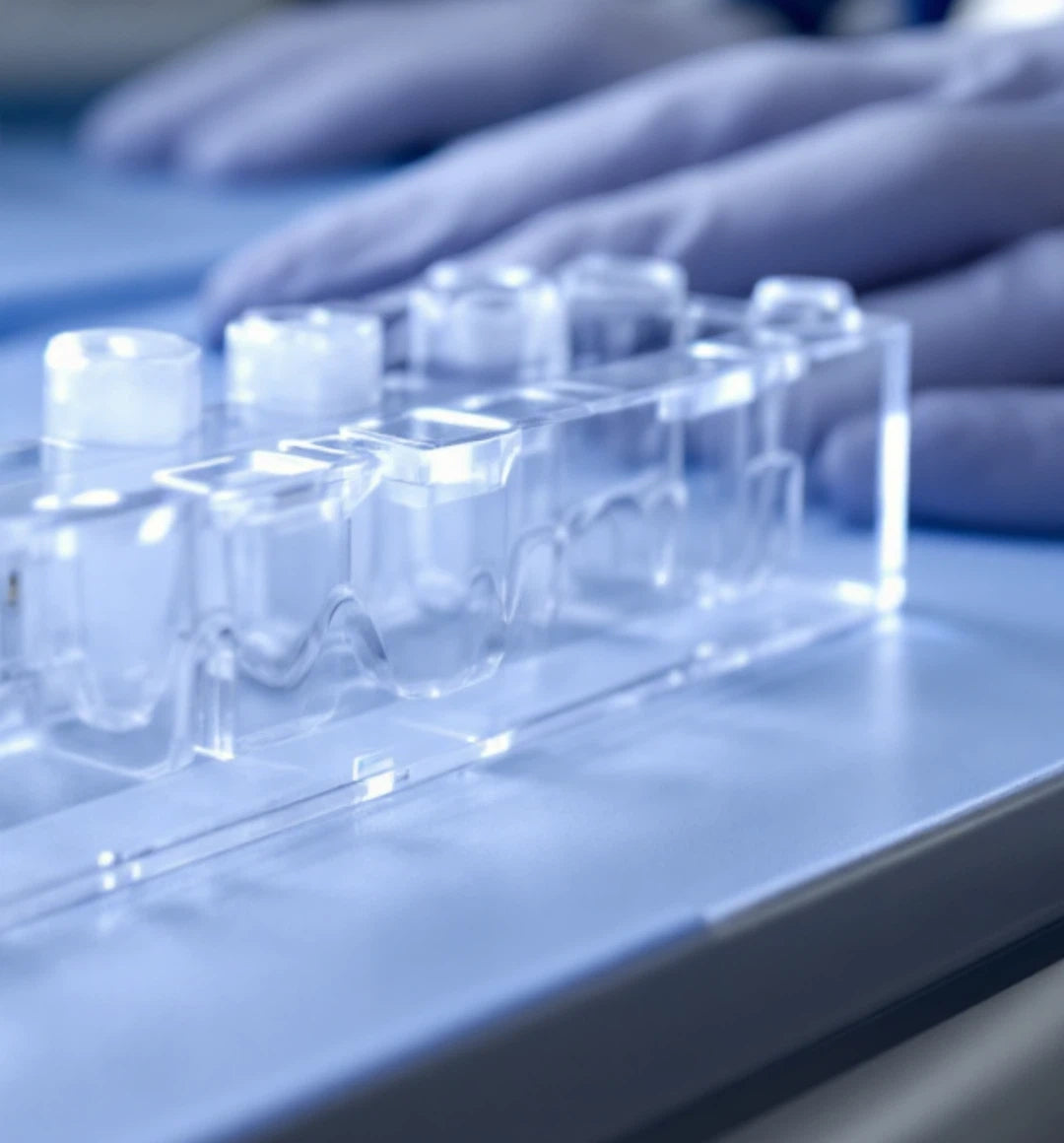

Transparent Resin – Optical Clarity & High Detail

Transparent Resin is used for optical components, fluid flow models & lighting designs where high transparency is required.

Advantages:

✔ Optical transparency

✔ Smooth, polishable surface

✔ Perfect for optical & design prototypes

High Temperature Resin – Extreme Heat Resistance

High Temperature Resin can withstand up to 280°C, making it perfect for high temperature applications, molds & industrial testing.

Advantages:

✔ Withstands temperatures up to 280°C

✔ Low shrinkage & high dimensional stability

✔ Perfect for mold casting & technical components

From startups to established companies - we create solutions that suit you

Our customers – Innovation in collaboration

Let us help you choose the optimal 3D printing solution!

Contact Maker Factory – Get the Right 3D Printing Technology for Your Project

Are you unsure which 3D printing technology is best suited for your project?

At Maker Factory, we advise companies, engineers, designers and product developers in choosing the right 3D printing technology for everything from prototypes and functional components to industrial solutions and custom-made models.