What is FDM 3D Printing?

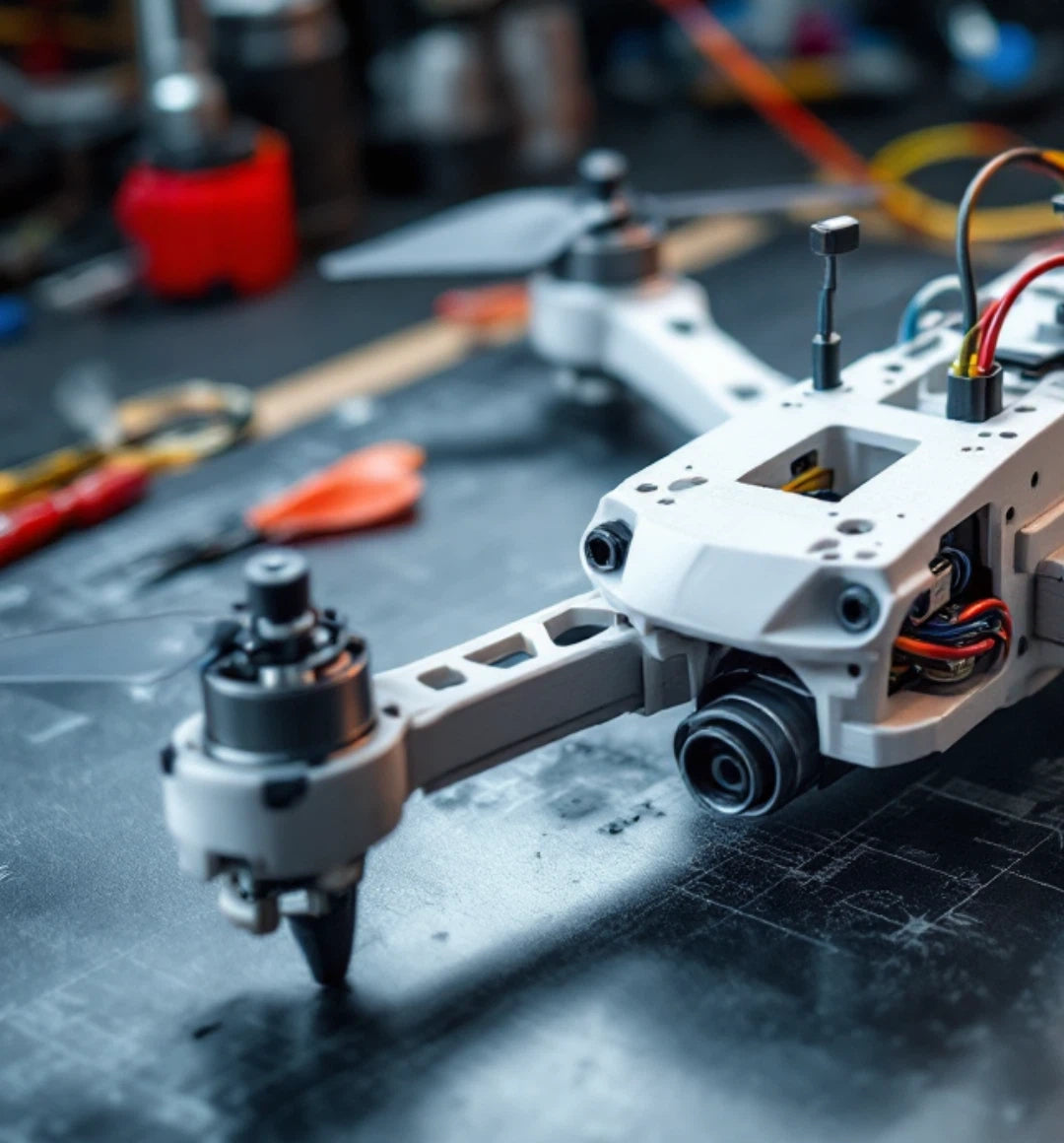

FDM (Fused Deposition Modeling) is one of the most widely used 3D printing technologies, known for its strength, durability and cost-effectiveness.

The technology works by melting and extruding thermoplastic filament, which builds a precise and robust object layer by layer. FDM is ideal for functional prototypes, spare parts, industrial components and large prints where durability and economy are essential.

Maker Factory offers high-quality FDM printing, optimized for your needs, whether it's product development, engineering, or hobby projects.

What Materials Can Be Used With FDM?

Introduction to FDM Materials

FDM 3D printing supports a wide range of thermoplastic materials, each with unique properties depending on your project needs.

At Maker Factory we offer the following FDM materials:

PLA (Polylactic Acid) – User-friendly & Eco-friendly

PLA is a bio-based and easily printable material that is ideal for prototypes, models and lightly functional parts. It has a smooth surface finish and high detail sharpness, but has low heat resistance, making it less suitable for technical applications.

Advantages:

✔ Easy to print with minimal warping

✔ Environmentally friendly & biodegradable

✔ Smooth finish, perfect for visual models

PETG (Polyethylene Terephthalate Glycol) – Impact Resistant & Weather Resistant

PETG combines the strength of ABS with the printability of PLA and is a popular choice for functional prototypes, containers and technical components.

Advantages:

✔ High impact strength & flexibility

✔ Resistant to moisture & chemicals

✔ Suitable for both indoor & outdoor use

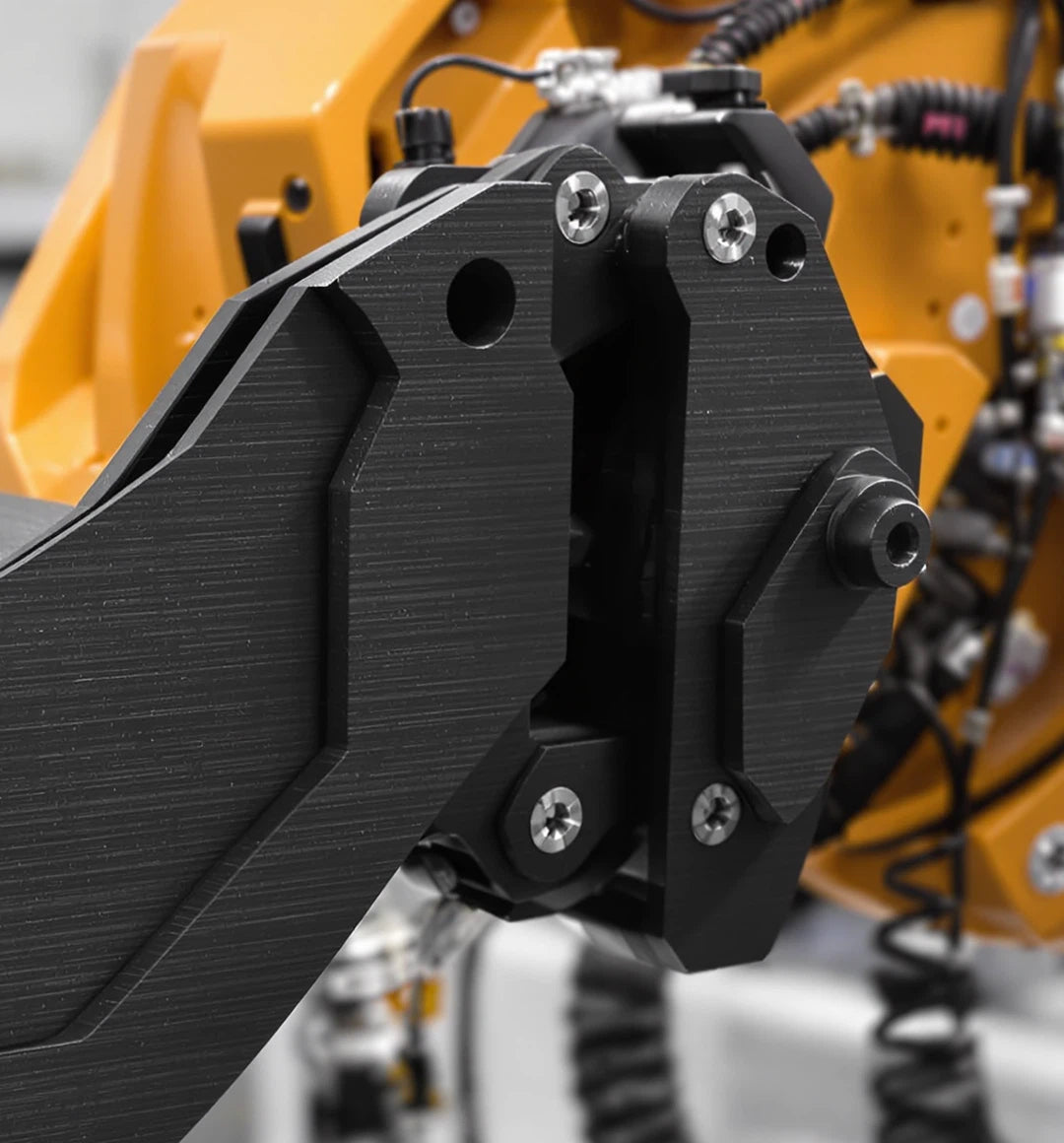

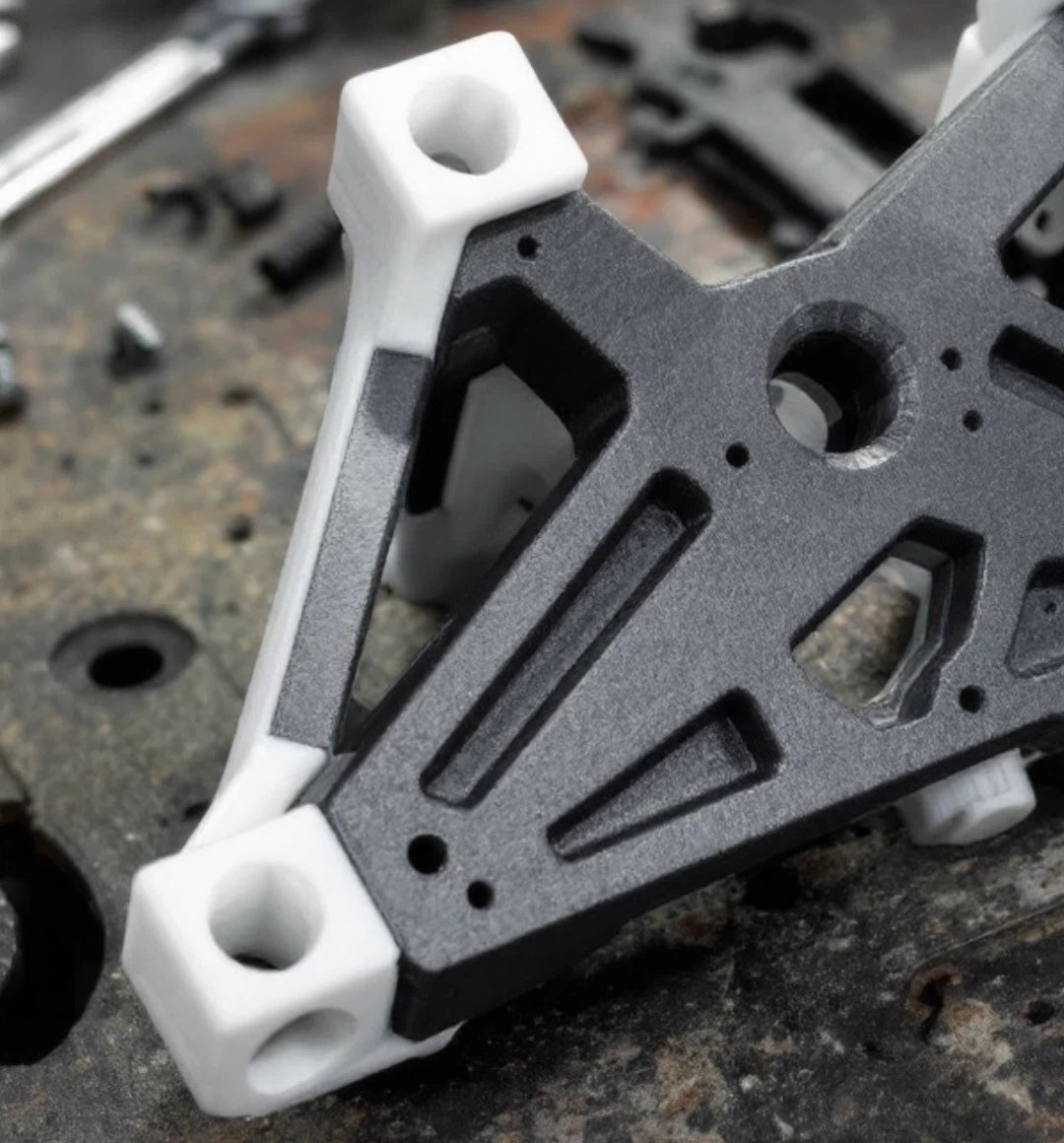

PETG-CF (Carbon Fiber Reinforced PETG) – Lightweight, Stiff & Durable

PETG-CF is PETG reinforced with carbon fiber, which provides increased stiffness, higher heat resistance and improved wear resistance.

Advantages:

✔ Low weight combined with high strength

✔ Improved heat resistance

✔ Less warping than standard PETG.

PC (Polycarbonate) – High Strength & Heat Resistant

PC is an extremely strong & heat-resistant material used in industrial applications and technical parts.

Advantages:

✔ Withstands temperatures up to 110°C

✔ Very high impact resistance

✔ Perfect for engineering & mechanical components

PC-FR (Flame Retardant Polycarbonate) – Safety & Durability

PC-FR is a flame-retardant version of PC, which is used in electronics, automotive and industrial applications.

Advantages:

✔ UL94 V0 certified flame retardant

✔ High mechanical strength

✔ Ideal for electrical & fire critical applications

PA6-CF (Nylon-Carbon Fiber) – Extreme Strength & Mechanical Durability

PA6-CF combines the strength of nylon with carbon fiber reinforcement, making it perfect for highly stressed mechanical parts.

Advantages:

✔ Very high mechanical strength

✔ Low weight & high heat resistance

✔ Perfect for technical components

TPU 95A – Flexible & Durable

TPU 95A is a semi-flexible material that combines impact resistance with elasticity, making it ideal for shock absorbers, seals and flexible functional parts.

Advantages:

✔ Moderate flexibility with high abrasion resistance

✔ Resistant to oil & chemicals

✔ Perfect for gaskets & protective parts

TPU 65D – Semi-Flexible & Shock Absorbing

TPU 65D is more rigid than TPU 95A, but still has moderate elastic properties, making it ideal for industrial seals, damping components and durable mechanical parts.

Advantages:

✔ High wear resistance & mechanical durability

✔ Resistant to chemicals & oil

✔ Ideal for technical applications

ASA – UV & Weather Resistant For Outdoor Use

ASA is a strong & UV-resistant material that does not yellow or degrade from sunlight, making it perfect for outdoor components.

Advantages:

✔ UV & weather resistant

✔ Strong & chemical resistant

✔ Perfect for automotive & industrial components

ABS – Impact Resistant, Heat Resistant & Easy To Process

ABS is a durable and easily machined material used in mechanical parts, electronics and industrial equipment.

Advantages:

✔ High impact resistance & heat resistance

✔ Can be treated with acetone vapor

✔ Ideal for functional prototypes & mechanical parts

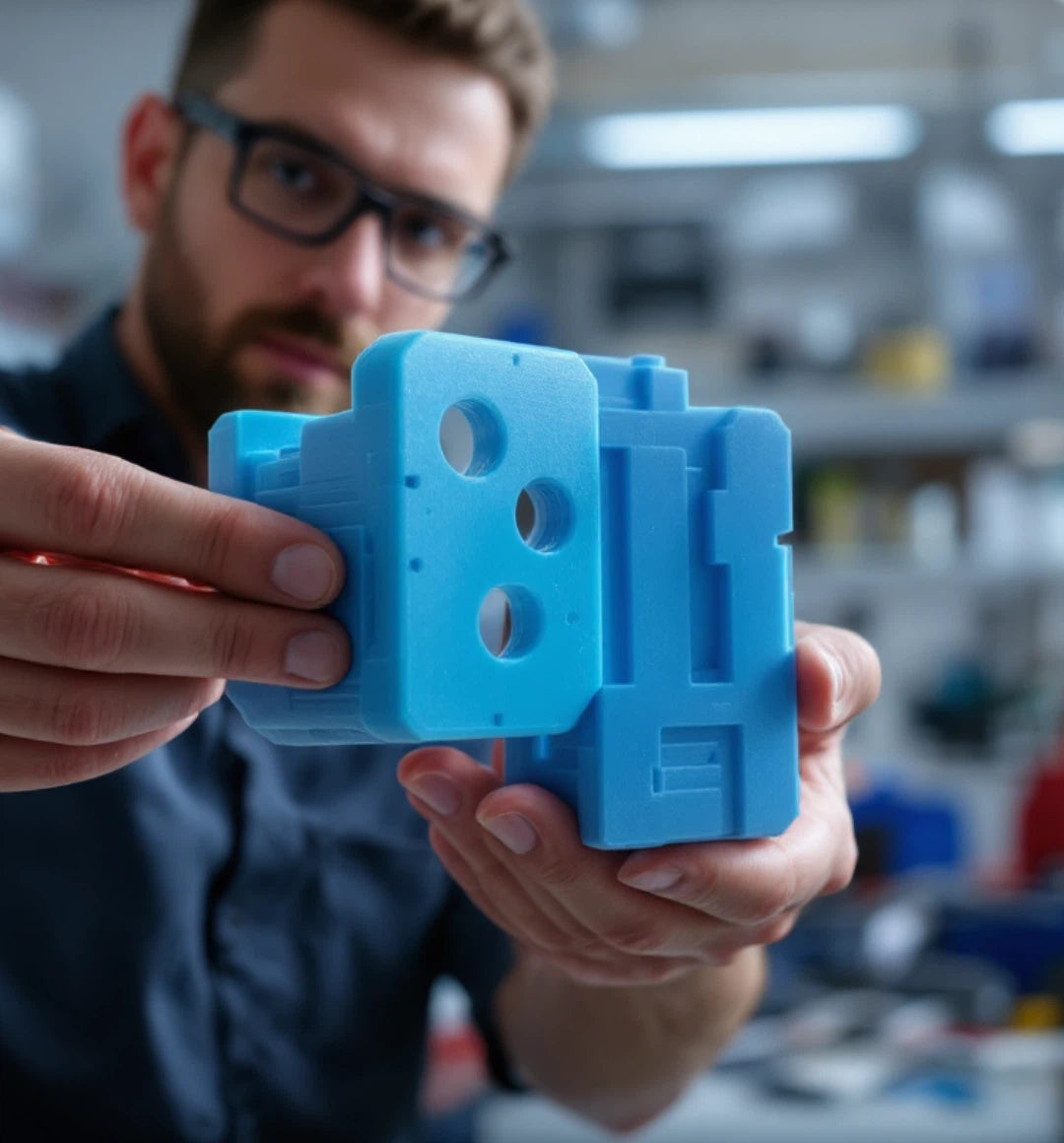

From startups to established companies - we create solutions that suit you

Our customers – Innovation in collaboration

Let us help you choose the optimal 3D printing solution!

Contact Maker Factory – Get the Right 3D Printing Technology for Your Project

Are you unsure which 3D printing technology is best suited for your project?

At Maker Factory, we advise companies, engineers, designers and product developers in choosing the right 3D printing technology for everything from prototypes and functional components to industrial solutions and custom-made models.