3D Printing for the Food Industry & Packaging – Efficient Solutions for Production & Development

The food industry requires hygienic, durable and precise solutions that can withstand high temperatures, moisture and chemicals. With 3D printing, you can develop custom tools, packaging models and production components without the high costs of traditional manufacturing methods.

At Maker Factory, we deliver customized solutions for production optimization, food-approved parts, and prototypes so companies can test and adapt packaging or production equipment faster than ever before.

From Prototype to Series Production – Without Limits

Durable & High-Performance Materials For Any Industry

Scale Production Faster – No Expensive Molds

Advanced 3D Printing Technology For Industrial Solutions

Customized, food-approved and sustainable – 3D printing makes your production more efficient.

Benefits of 3D Printing for the Food Industry & Packaging

In the food industry, hygiene, precision and rapid adaptation are essential. 3D printing makes it possible to produce food-approved components, custom production tools and packaging prototypes, without long production runs or high development costs.

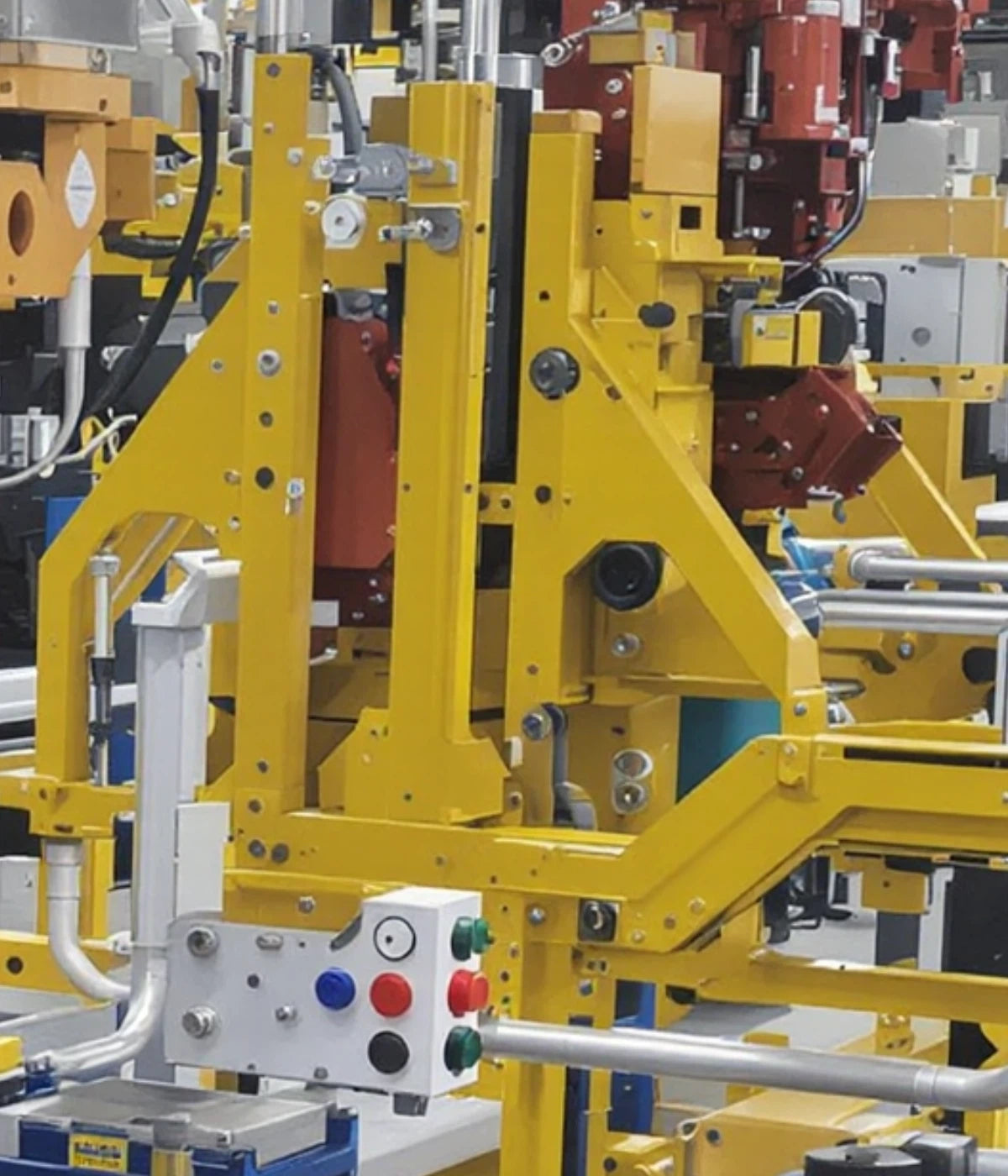

With 3D printing, you can quickly test new packaging designs, create custom fixtures for production lines, and produce durable parts that can withstand both high temperatures and frequent cleaning. The flexibility of 3D printing means companies can optimize their production equipment and reduce costs without compromising quality.

Materials Customized Food Industry & Packaging

Materials Customized Food Industry & Packaging

The food industry places high demands on materials that are safe, easy to clean, and resistant to temperature fluctuations and chemicals. With 3D printing, you can choose materials that are certified for food contact, can withstand heat treatment, and have a smooth surface for optimal hygiene.

From food-grade plastics to chemical-resistant solutions, our materials provide high strength, long durability and increased flexibility in the production environment.

PETG (Polyethylene Terephthalate Glycol) – Impact Resistant & Weather Resistant

PETG combines the strength of ABS with the printability of PLA and is a popular choice for functional prototypes, containers and technical components.

Advantages:

✔ High impact strength & flexibility

✔ Resistant to moisture & chemicals

✔ Suitable for both indoor & outdoor use

TPU 95A – Flexible & Durable

TPU 95A is a semi-flexible material that combines impact resistance with elasticity, making it ideal for shock absorbers, seals and flexible functional parts.

Advantages:

✔ Moderate flexibility with high abrasion resistance

✔ Resistant to oil & chemicals

✔ Perfect for gaskets & protective parts

From startups to established companies - we create solutions that suit you

Our customers – Innovation in collaboration

Let us help you choose the optimal 3D printing solution!

Get the Right 3D Printing Solution for Your Industry

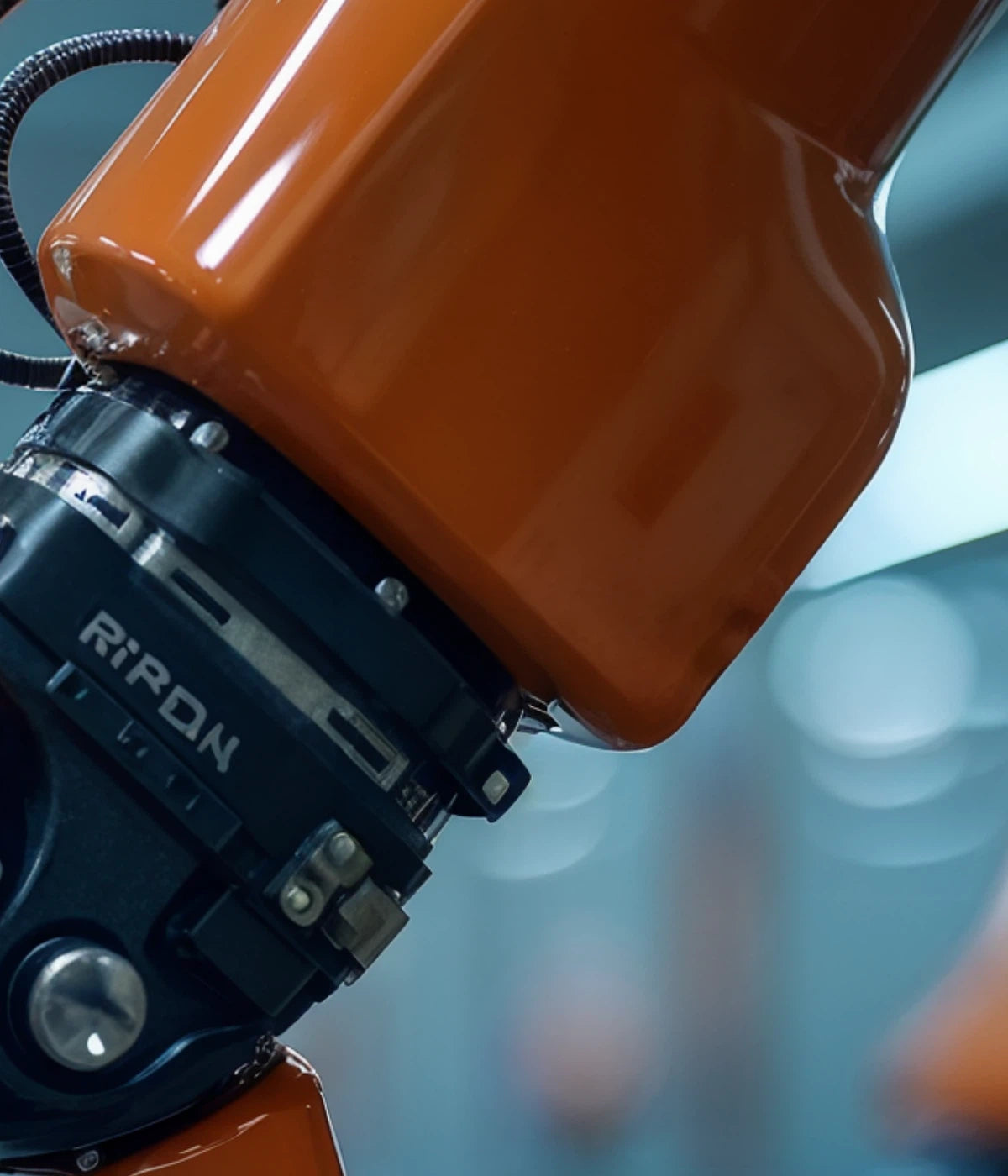

At Maker Factory, we advise manufacturing companies, engineers and development departments in choosing the right 3D printing technology for everything from machine parts and production tools to technical prototypes and custom-made industrial components.

Let us help you choose the optimal solution for your industry!