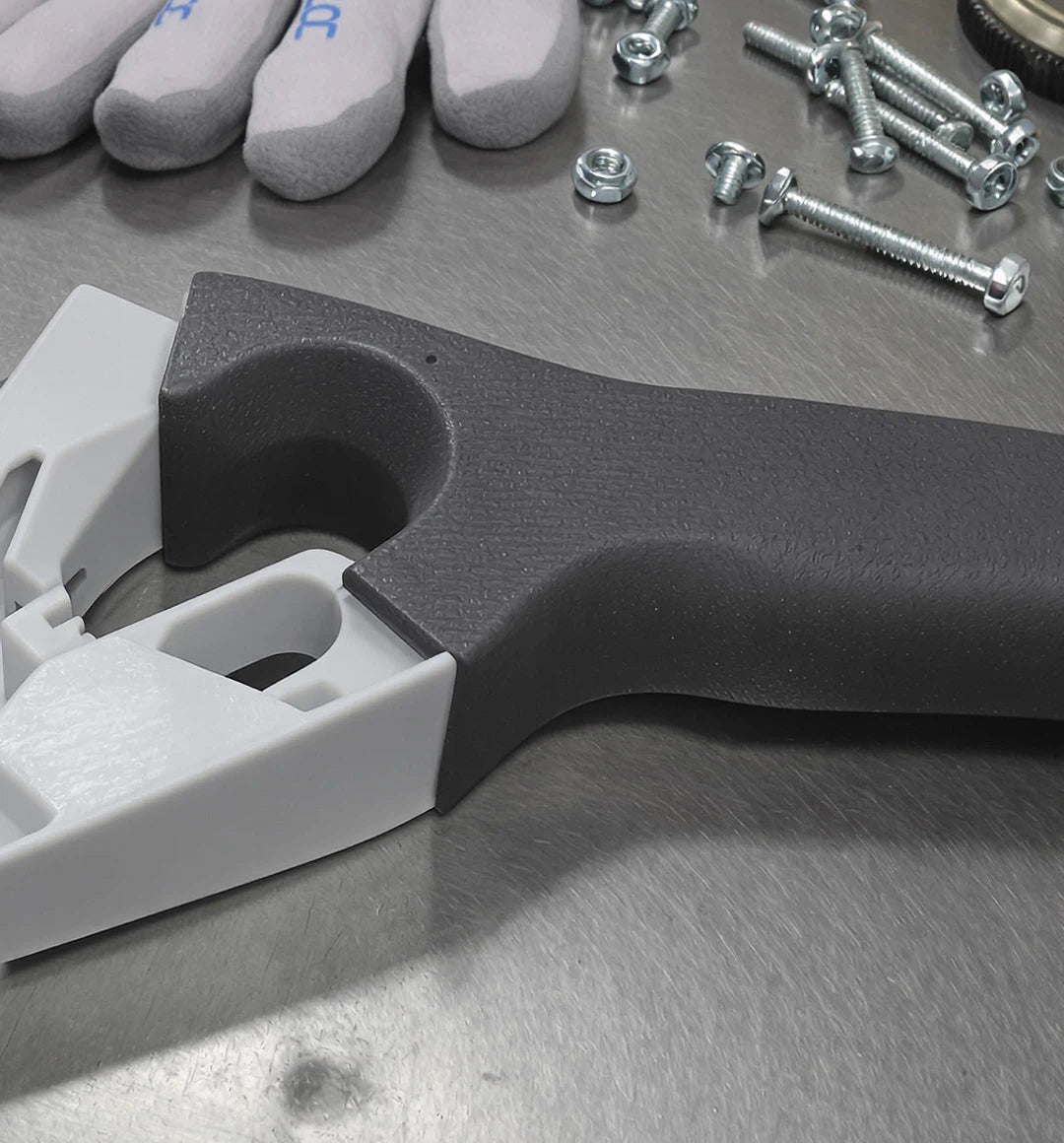

TPU 95A – Flexible & Durable For Shock Absorbing Applications

TPU 95A (Thermoplastic Polyurethane) is a flexible, durable and chemical-resistant 3D printing material that combines rubber-like properties with the durability of plastic.

With a Shore A hardness of 95A, the material has high elasticity, making it ideal for shock absorbing parts, sealing rings, protective components and flexible couplings. TPU 95A can be bent and stretched, but returns to its original shape without damage.

The material has high wear resistance and good chemical resistance, making it useful in industrial applications, robotics, sports equipment and automotive components.

Properties of TPU 95A

TPU 95A is an elastic and durable material used for components that require flexibility, durability and chemical resistance.

- Elastic & flexible – Can be bent & stretched without losing shape

- High wear resistance – Resistant to mechanical stress

- Resistant to chemicals & oil – Perfect for industrial applications

- Good impact resistance & shock absorption – Absorbs vibrations & shocks

- Suitable for seals & protection – Rubber-like properties

Flexible & Shock Absorbing 3D Print With TPU 95A

TPU 95A is the perfect choice for applications where flexibility, durability and abrasion resistance are important factors. The material is resistant to chemicals, oil and mechanical abrasion, making it ideal for rubber components, seals, hoses and shock absorbers.

With a Shore A hardness of 95A, TPU 95A is soft and flexible, yet still firm enough to maintain its shape under load. It can be used in industrial manufacturing, robotics, sporting goods, and automotive applications.

The material also has high impact resistance and can absorb vibrations, making it suitable for damping elements and protective parts. TPU 95A is a reliable choice for both technical and functional prints.

Technical Specification For TPU 95A

| Egenskab | TPU 95A (Fleksibelt Polyurethan) |

|---|---|

| Materialetype | Termoplastisk Polyurethan (TPU) |

| Tolerancer | ± 0,2 mm |

| Shore Hårdhed | 95A |

| Forlængelse ved brud | 400-600 % |

| Densitet | 1,2 g/cm³ |

| Slidstyrke | Høj |

| Kemikaliebestandighed | Modstandsdygtig mod olie, fedt & opløsningsmidler |

| Slagfasthed | Meget høj |

| Printtemperatur | 220-250°C |

| Byggepladetemp. | 30-60°C |

| Efterbehandling | Slibning, limning, varmeformning |

Advantages of TPU 95A

- Flexible & elastic – Perfect for moving parts

- High wear resistance & impact resistance

- Resistant to oil, chemicals & solvents

- Ideal for seals, shock absorption & protective parts

From startups to established companies - we create solutions that suit you

Our customers – Innovation in collaboration

Professional 3D Printing Materials For Precise & Durable Results

Contact Maker Factory – Get the Right 3D Printing Material for Your Project

Are you unsure which 3D printing material is best suited for your project?

At Maker Factory, we advise companies, engineers, designers and hobbyists within prototypes, product development, model building and industrial design.

We offer a wide selection of high-quality 3D printing materials, including PLA, PETG, ABS, TPU and specialty materials, so you get the perfect material tailored to your needs.