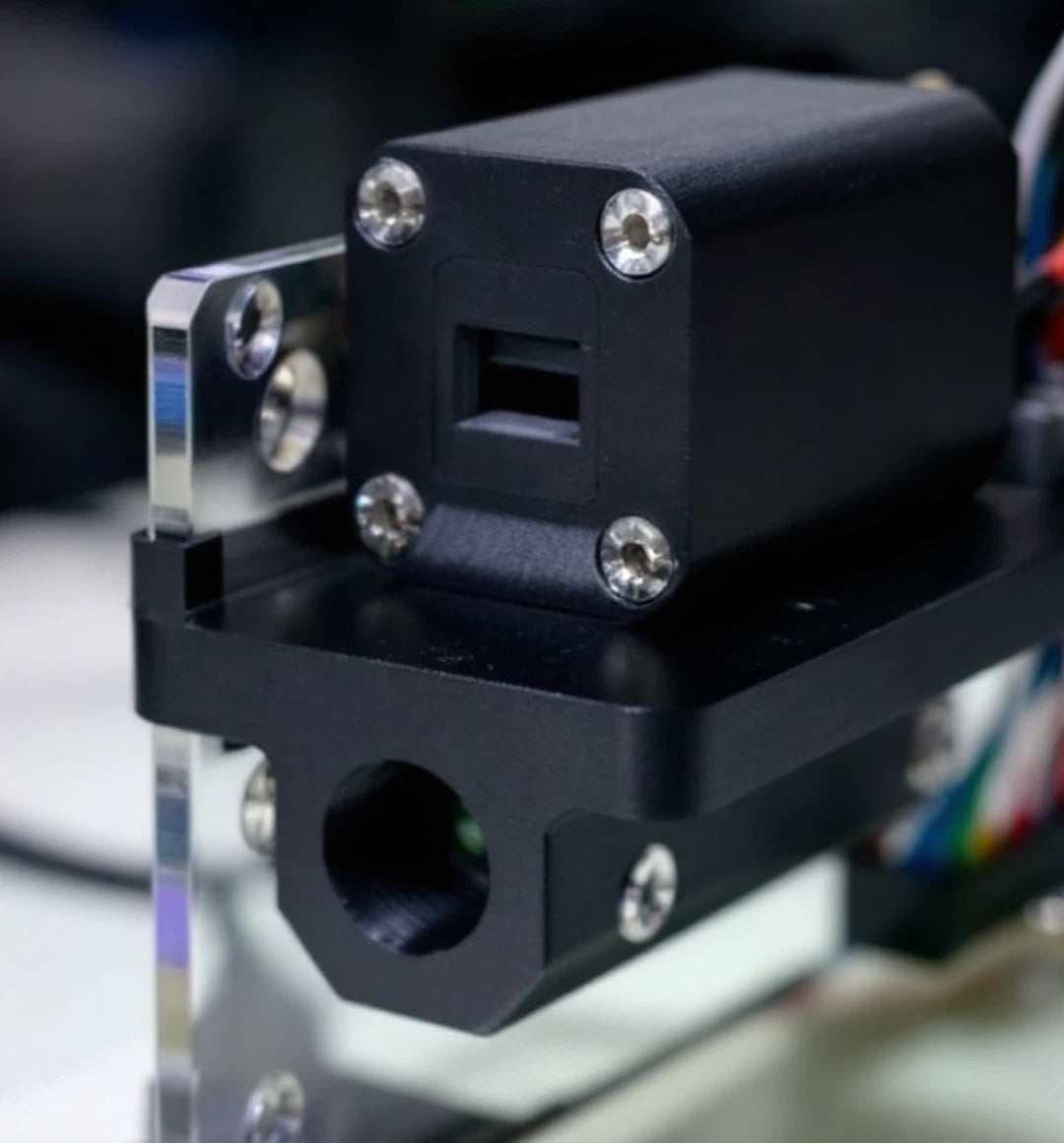

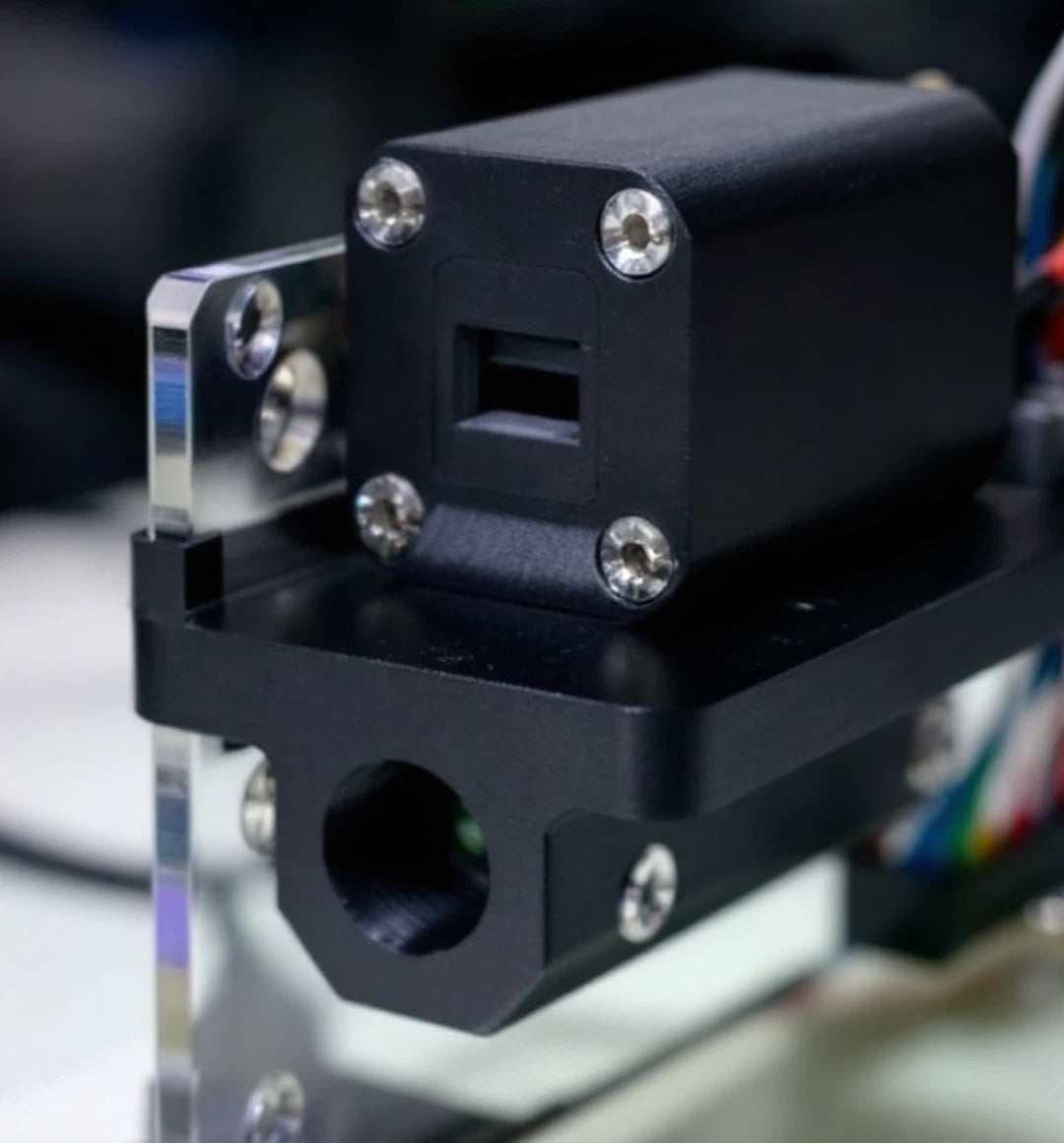

3D Printing for Machine Building & Automation – Faster Development & Optimized Production

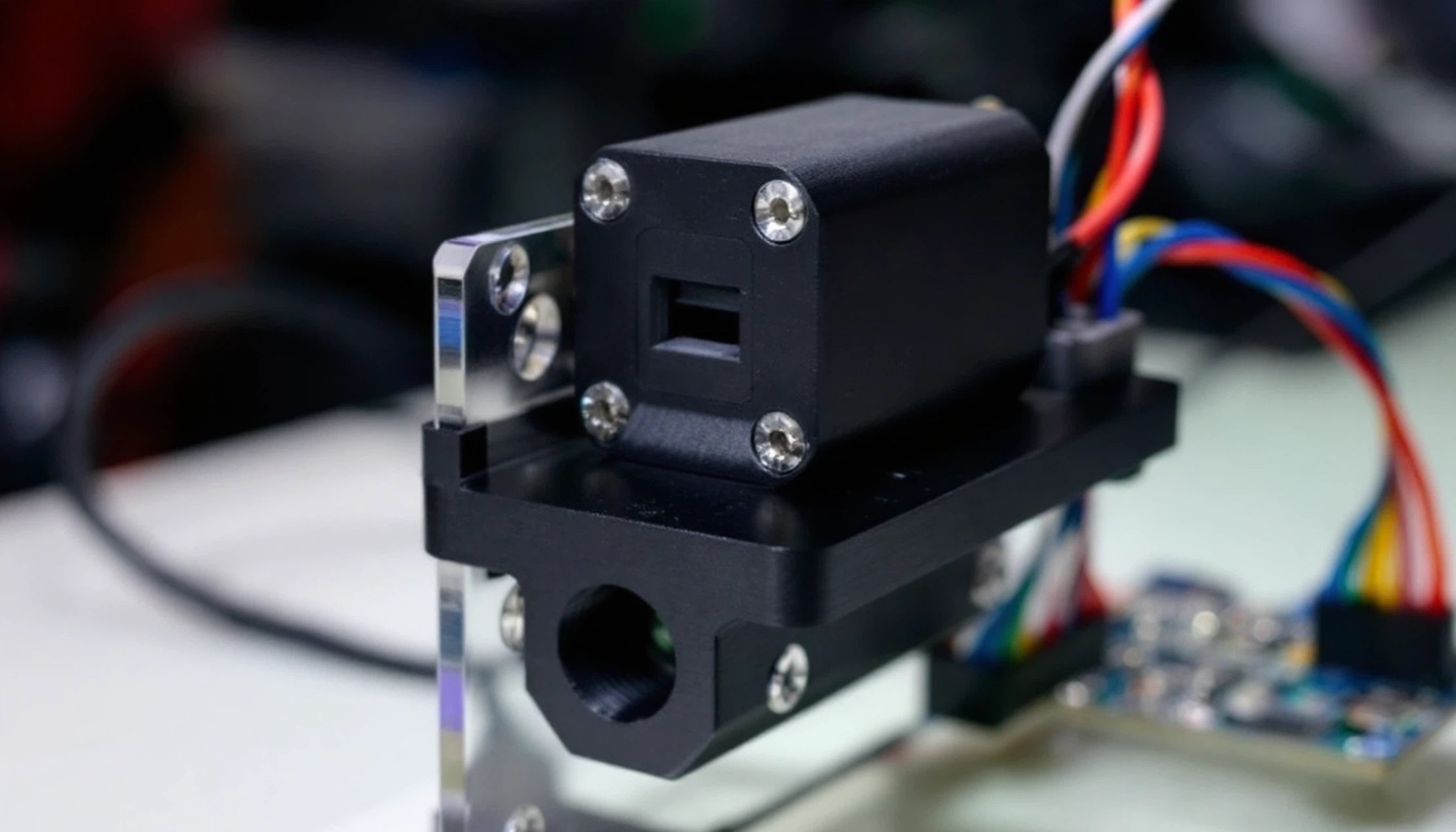

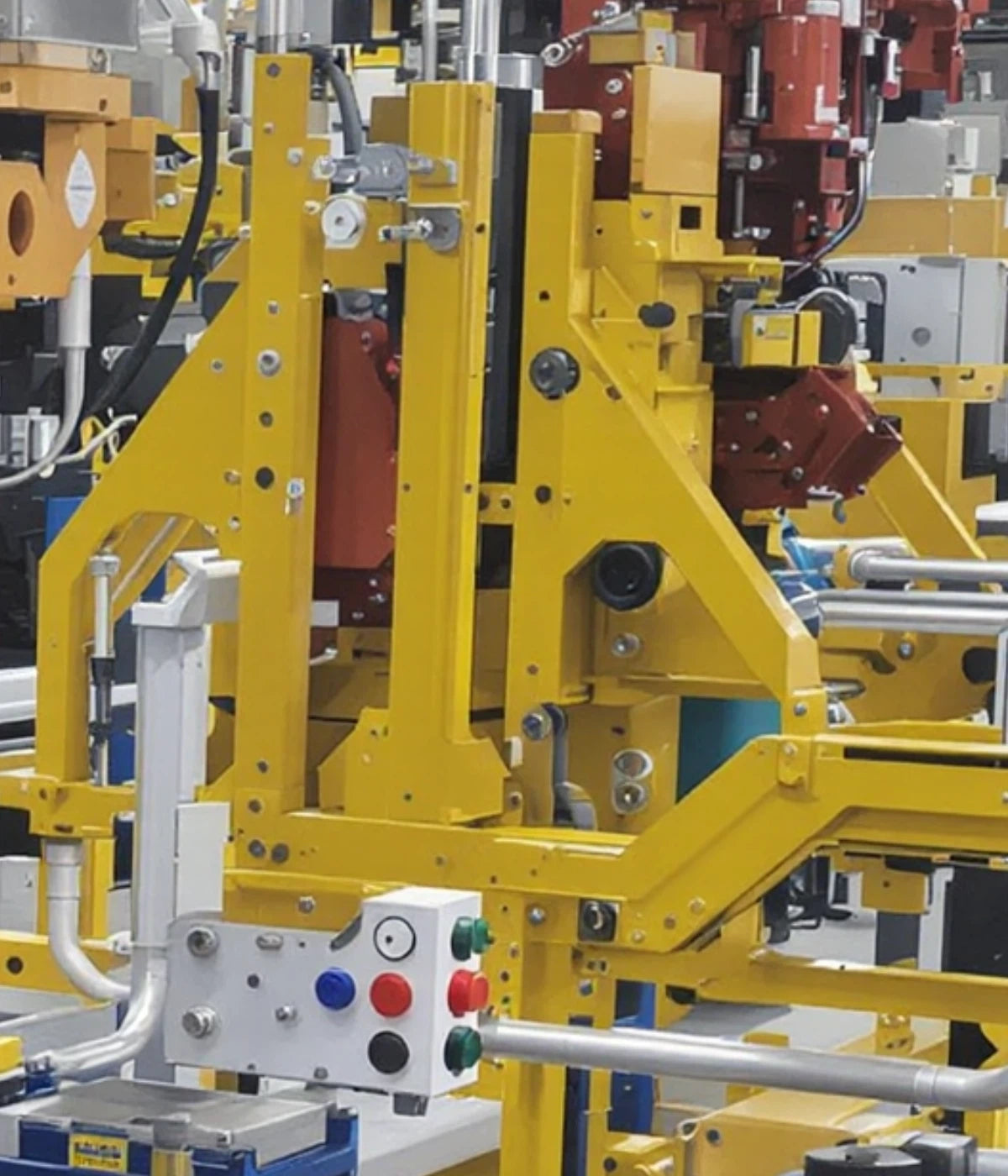

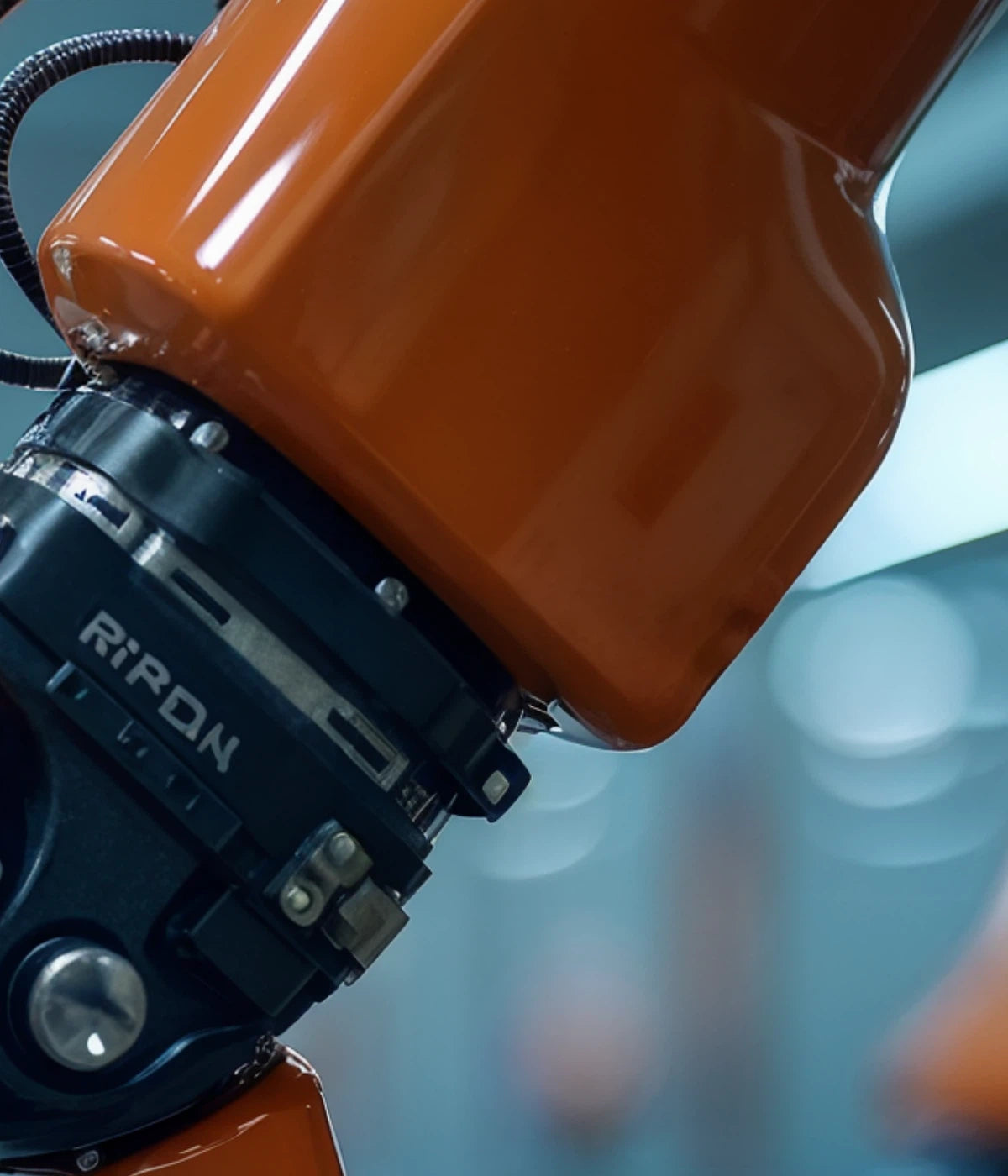

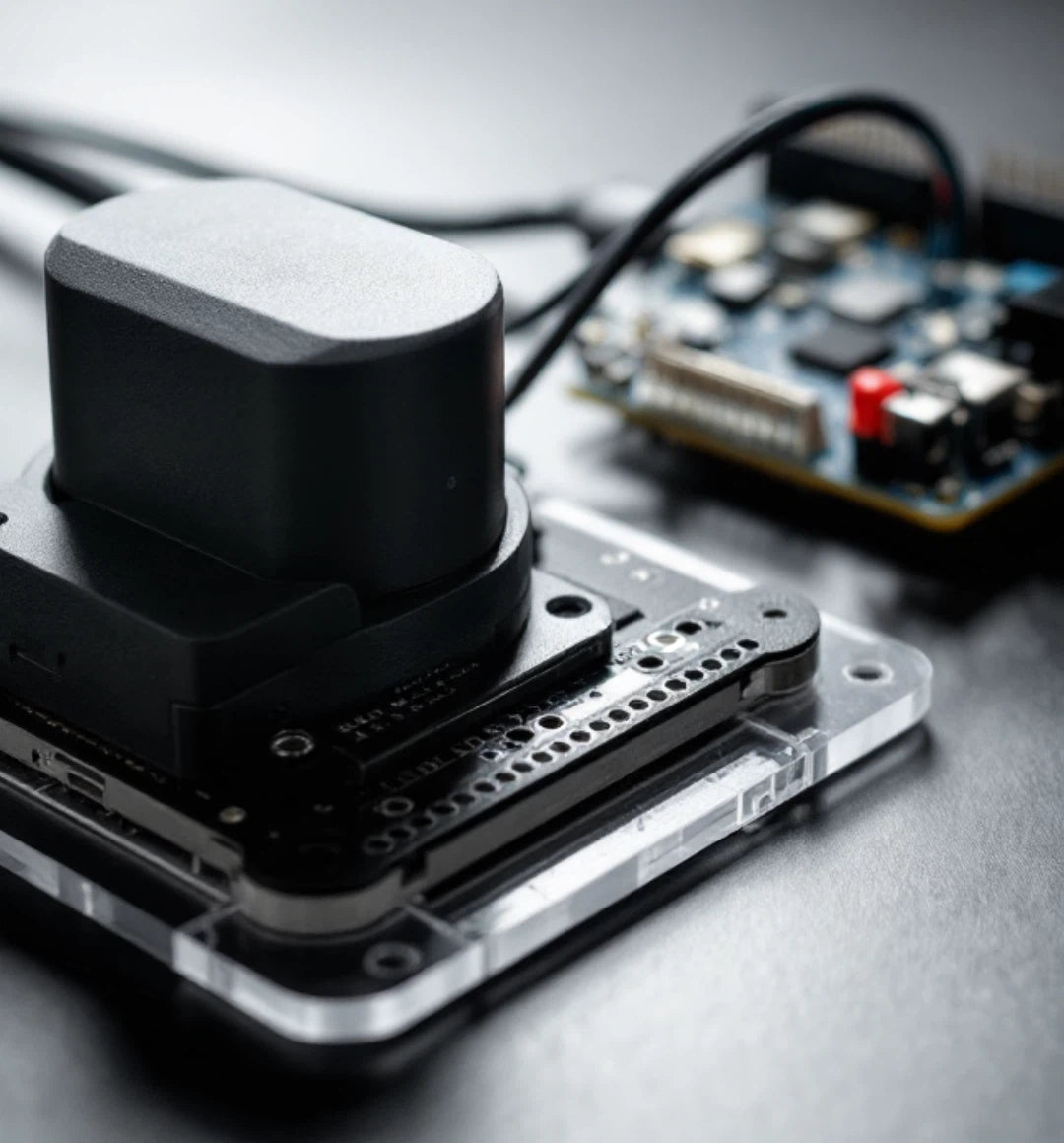

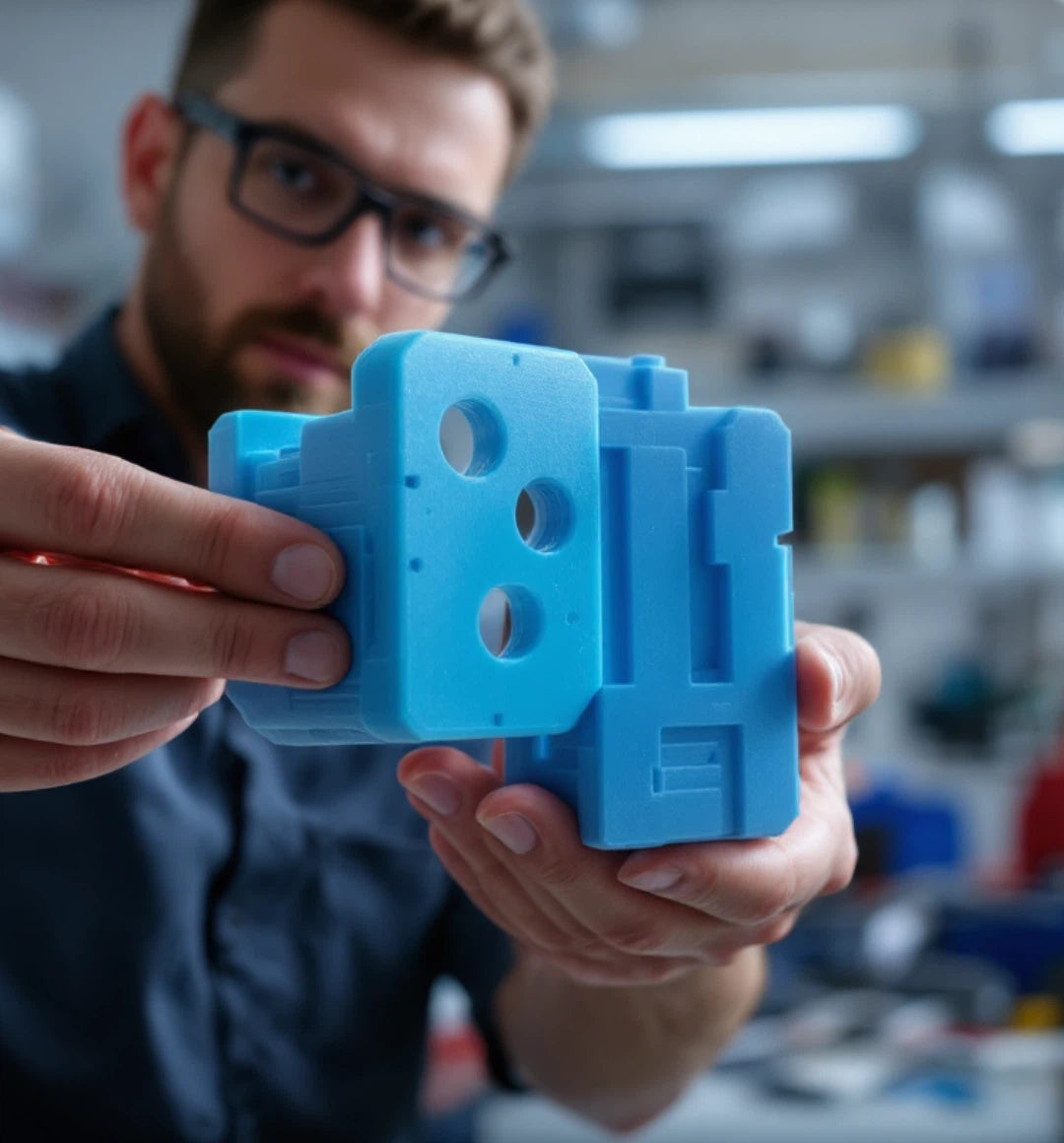

In machine building and automation, high precision, mechanical strength and rapid adaptation are essential. With 3D printing, companies can produce customized fittings, functional prototypes and robust components that improve operational reliability and minimize downtime.

At Maker Factory, we help machine builders and automation specialists develop custom-designed production parts, optimized fixtures, and durable components that withstand demanding industrial environments.

From Prototype to Series Production – Without Limits

Durable & High-Performance Materials For Any Industry

Scale Production Faster – No Expensive Molds

Advanced 3D Printing Technology For Industrial Solutions

Maximum flexibility, reduced costs and precision manufacturing – 3D printing creates the machine parts of the future.

Advantages of 3D Printing for Mechanical Engineering & Automation

In machine building and automation, precision, durability and flexibility are essential for efficient production. With 3D printing, you can produce customized components quickly and cost-effectively without the need for expensive tooling. The technology enables rapid iteration, lightweight optimization and the production of complex geometries that cannot be created with traditional methods.

3D printing makes it easy to replace or optimize machine components, reducing downtime and improving overall productivity. Meanwhile, materials with high mechanical strength ensure your parts can withstand wear, vibration, and stress in demanding production environments.

"Reduce downtime, optimize production and get stronger components – 3D printing is the future of machine building and automation."

Maximum strength, minimal weight and optimized performance – materials designed for industry.

Materials Customized Machine Building & Automation

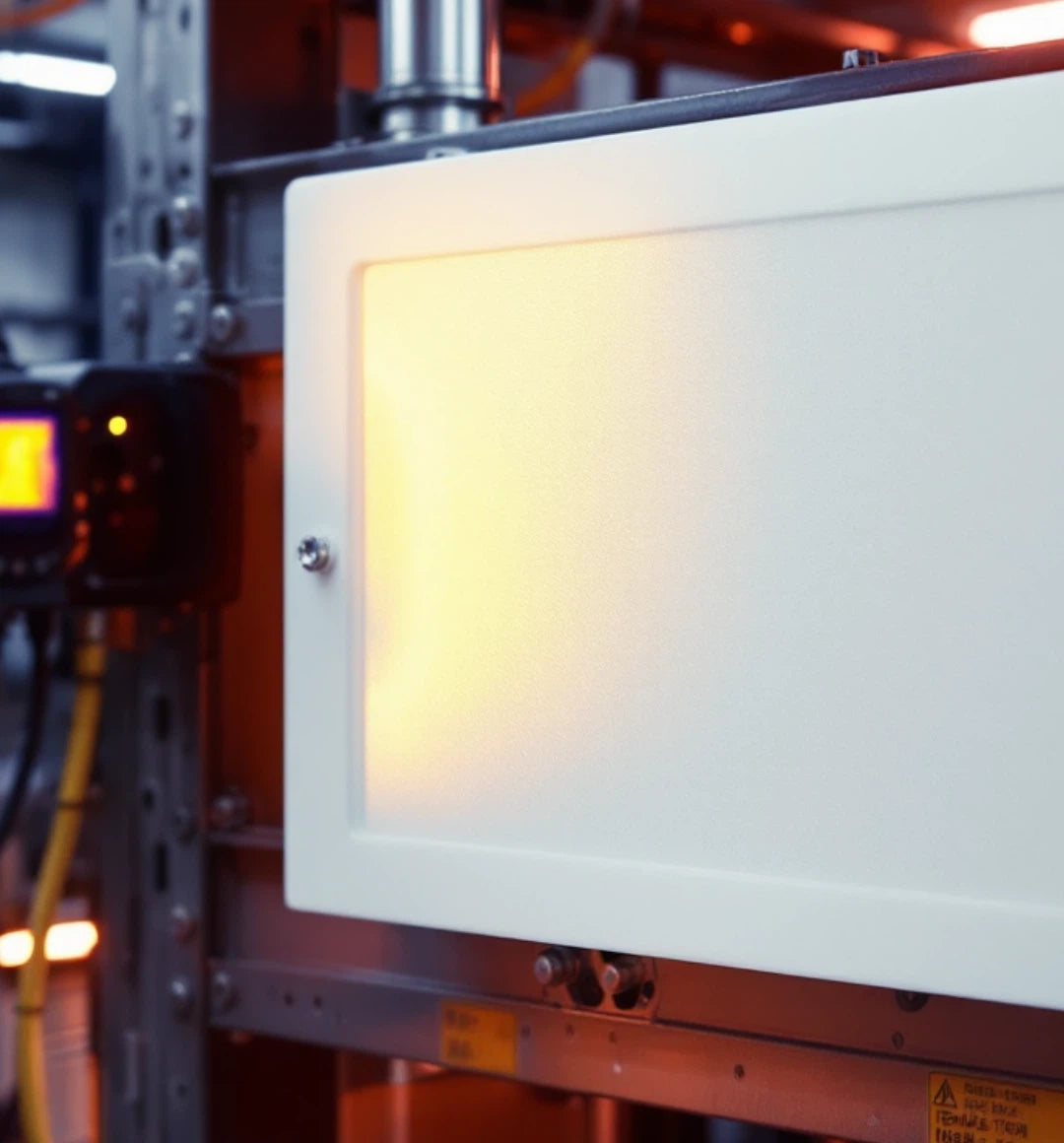

The mechanical engineering industry places high demands on strength, wear resistance and temperature resistance. With 3D printing, you can choose materials that can withstand high loads, friction and chemicals, while optimizing the performance and lifespan of the machine.

PETG (Polyethylene Terephthalate Glycol) – Impact Resistant & Weather Resistant

PETG combines the strength of ABS with the printability of PLA and is a popular choice for functional prototypes, containers and technical components.

Advantages:

✔ High impact strength & flexibility

✔ Resistant to moisture & chemicals

✔ Suitable for both indoor & outdoor use

PETG-CF (Carbon Fiber Reinforced PETG) – Lightweight, Stiff & Durable

PETG-CF is PETG reinforced with carbon fiber, which provides increased stiffness, higher heat resistance and improved wear resistance.

Advantages:

✔ Low weight combined with high strength

✔ Improved heat resistance

✔ Less warping than standard PETG.

PC (Polycarbonate) – High Strength & Heat Resistant

PC is an extremely strong & heat-resistant material used in industrial applications and technical parts.

Advantages:

✔ Withstands temperatures up to 110°C

✔ Very high impact resistance

✔ Perfect for engineering & mechanical components

PC-FR (Flame Retardant Polycarbonate) – Safety & Durability

PC-FR is a flame-retardant version of PC, which is used in electronics, automotive and industrial applications.

Advantages:

✔ UL94 V0 certified flame retardant

✔ High mechanical strength

✔ Ideal for electrical & fire critical applications

PA6-CF (Nylon-Carbon Fiber) – Extreme Strength & Mechanical Durability

PA6-CF combines the strength of nylon with carbon fiber reinforcement, making it perfect for highly stressed mechanical parts.

Advantages:

✔ Very high mechanical strength

✔ Low weight & high heat resistance

✔ Perfect for technical components

TPU 95A – Flexible & Durable

TPU 95A is a semi-flexible material that combines impact resistance with elasticity, making it ideal for shock absorbers, seals and flexible functional parts.

Advantages:

✔ Moderate flexibility with high abrasion resistance

✔ Resistant to oil & chemicals

✔ Perfect for gaskets & protective parts

TPU 65D – Semi-Flexible & Shock Absorbing

TPU 65D is more rigid than TPU 95A, but still has moderate elastic properties, making it ideal for industrial seals, damping components and durable mechanical parts.

Advantages:

✔ High wear resistance & mechanical durability

✔ Resistant to chemicals & oil

✔ Ideal for technical applications

ASA – UV & Weather Resistant For Outdoor Use

ASA is a strong & UV-resistant material that does not yellow or degrade from sunlight, making it perfect for outdoor components.

Advantages:

✔ UV & weather resistant

✔ Strong & chemical resistant

✔ Perfect for automotive & industrial components

ABS – Impact Resistant, Heat Resistant & Easy To Process

ABS is a durable and easily machined material used in mechanical parts, electronics and industrial equipment.

Advantages:

✔ High impact resistance & heat resistance

✔ Can be treated with acetone vapor

✔ Ideal for functional prototypes & mechanical parts

From startups to established companies - we create solutions that suit you

Our customers – Innovation in collaboration

Let us help you choose the optimal 3D printing solution!

Get the Right 3D Printing Solution for Your Industry

At Maker Factory, we advise manufacturing companies, engineers and development departments in choosing the right 3D printing technology for everything from machine parts and production tools to technical prototypes and custom-made industrial components.

Let us help you choose the optimal solution for your industry!