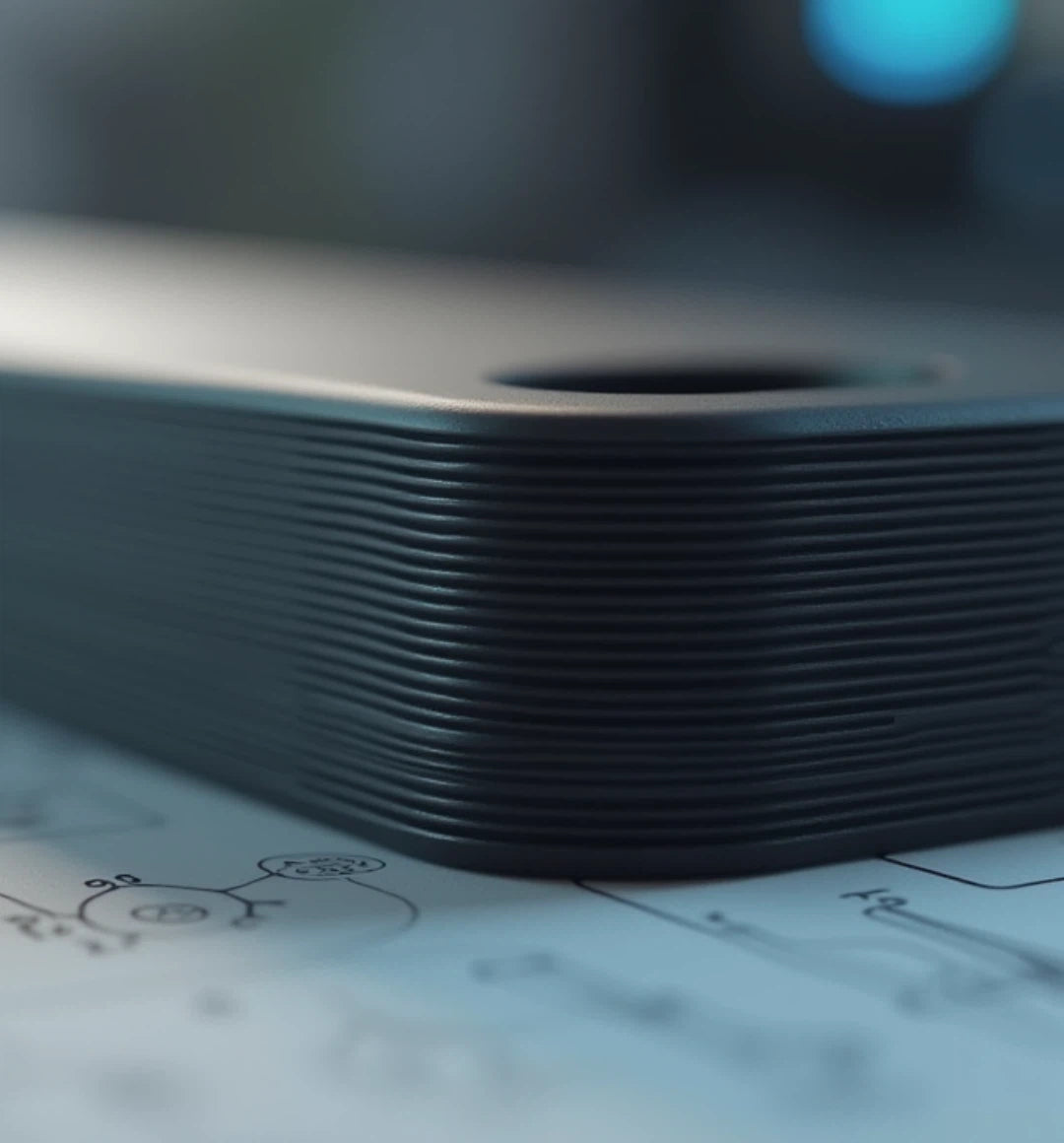

ABS – Strong & Resistant Material For Industrial Applications

ABS (Acrylonitrile Butadiene Styrene) is an impact-resistant, heat-resistant, and chemical-resistant 3D printing material that is often used in industry, product development, and mechanical applications.

ABS is known for its high strength and toughness, making it perfect for mechanical parts, functional prototypes, and rugged enclosures. The material has moderate flexibility, meaning it can absorb shock without breaking, and it can withstand higher temperatures than PLA and PETG.

ABS is easy to work with as it can be sanded, drilled, glued and finished with acetone vapor for a smooth finish. The material is commonly used in automotive, electronics, machine parts and industrial design where strength, durability and thermal stability are important factors.

Properties of ABS

ABS is a strong and easily processable material used for functional and mechanical parts with high durability.

- High strength & impact resistance – Perfect for mechanical & industrial components

- Heat resistant – Withstands up to 100°C without deformation

- Easy to process & finish – Can be sanded, drilled & glued

- Resistant to chemicals – Withstands oil, grease & solvents

- Dissolvable in acetone – Smooth finish & stronger layer bonding

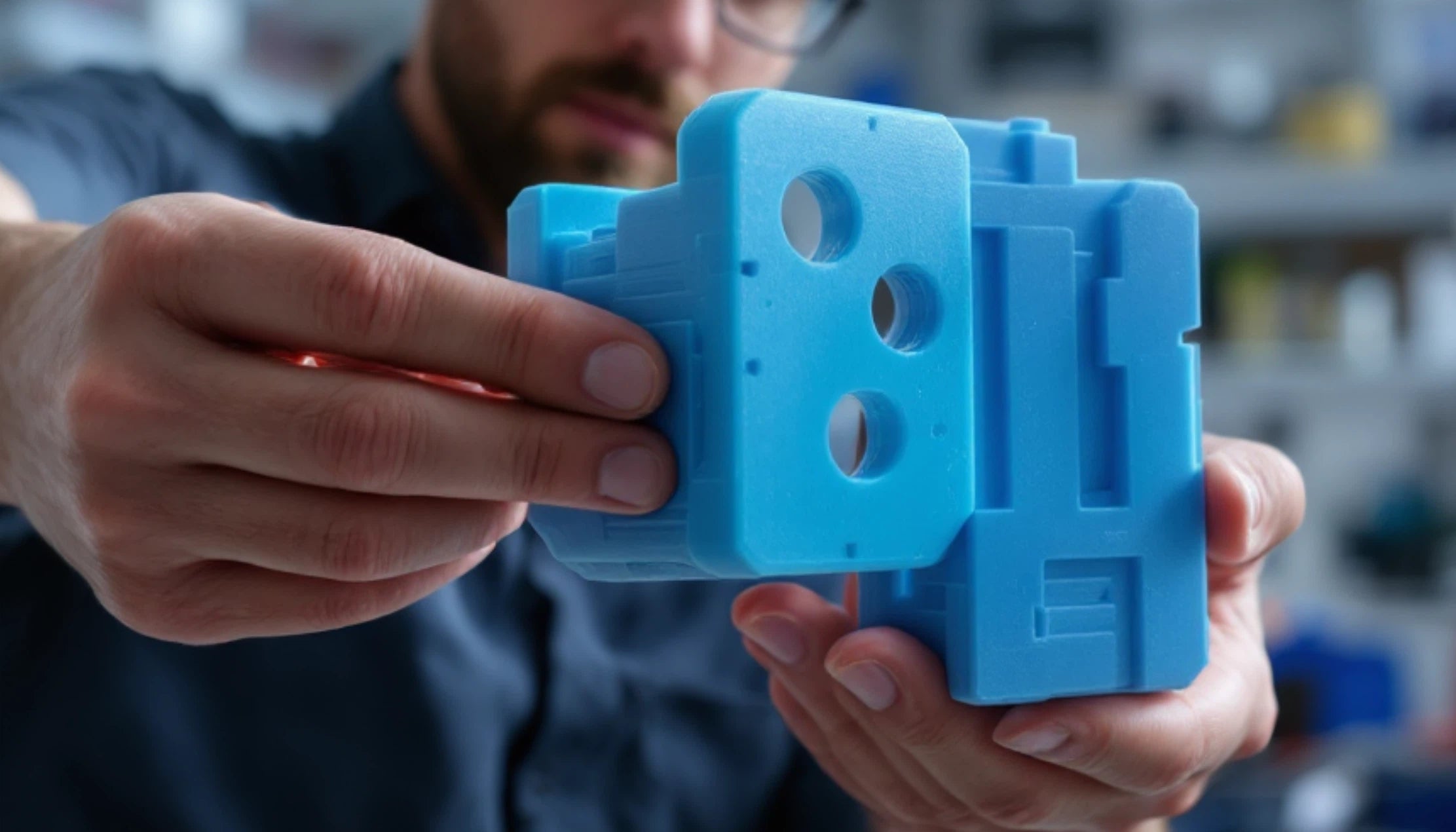

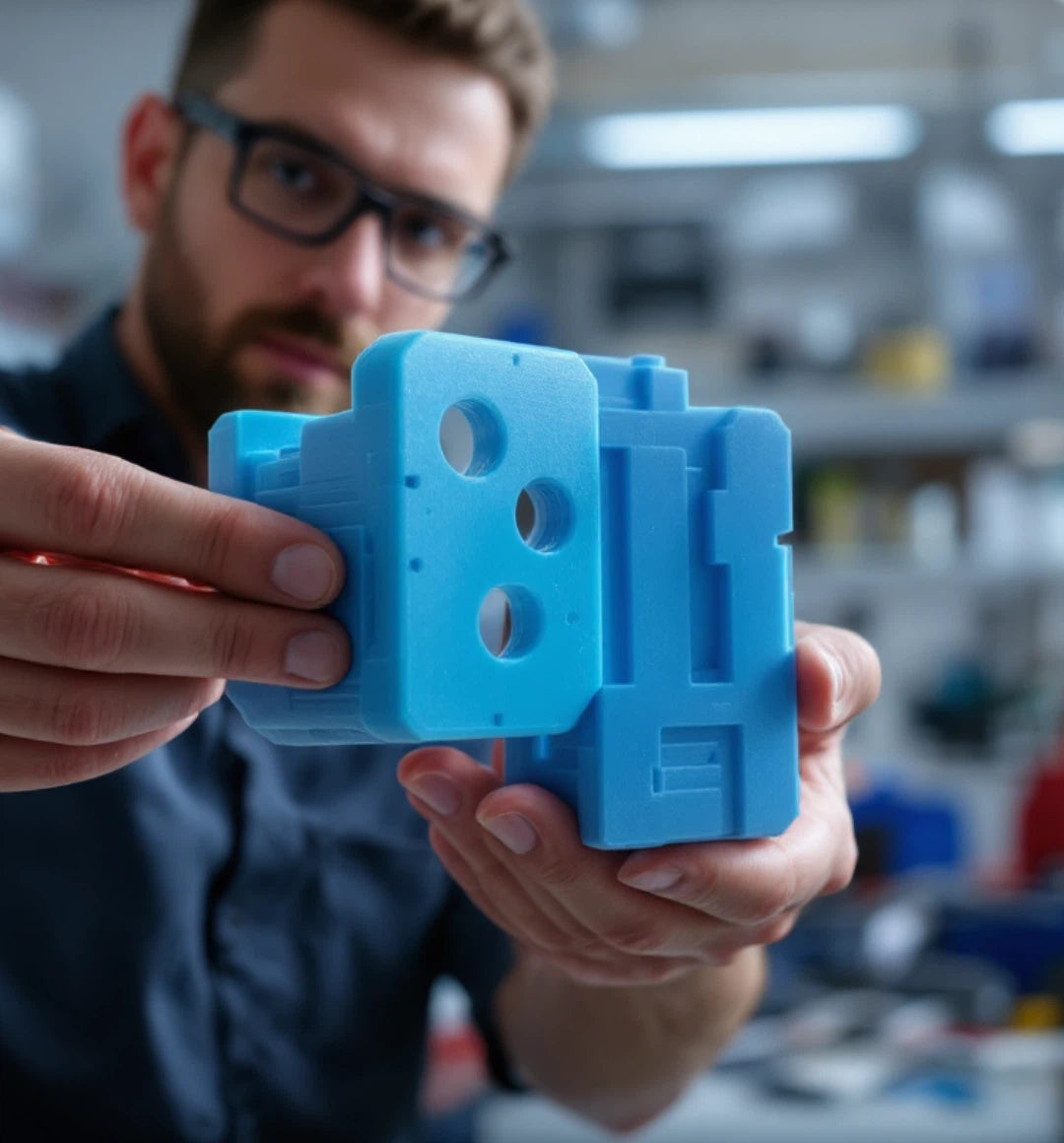

Impact-resistant & Industrial-strength 3D Print With ABS

ABS is one of the most widely used plastic materials in both industrial production and hobby projects. It is known for its impact resistance, heat resistance and durability, making it suitable for mechanical components, spare parts and technical prototypes.

Compared to PLA, ABS is more flexible and heat-tolerant, making it a better choice for functional parts that must withstand stress and heat.

ABS can be post-treated with acetone vapor, giving a smooth, shiny finish reminiscent of injection-molded plastic parts. It is also a preferred material in electronics, as it has good insulating properties and is resistant to chemicals.

Technical Specification For ABS

| Egenskab | ABS (Acrylonitrile Butadiene Styrene) |

|---|---|

| Materialetype | Acrylonitrile Butadiene Styrene (ABS) |

| Tolerancer | ± 0,1 mm |

| Trykstyrke | 40-65 MPa |

| Elasticitetsmodul | 2-2,5 GPa |

| Forlængelse ved brud | 10-25 % |

| Densitet | 1,03 g/cm³ |

| Smeltepunkt | 210-240°C |

| Glasovergangstemp. | 100-105°C |

| Warping | Moderat |

| Printtemperatur | 230-270°C |

| Byggepladetemp. | 90-110°C |

| Efterbehandling | Slibning, limning, maling, acetondampbehandling |

Advantages of ABS

- Impact & heat resistant

- Easy to refinish & polish

- Stronger & more flexible than PLA

- Ideal for mechanical components & functional parts

From startups to established companies - we create solutions that suit you

Our customers – Innovation in collaboration

Professional 3D Printing Materials For Precise & Durable Results

Contact Maker Factory – Get the Right 3D Printing Material for Your Project

Are you unsure which 3D printing material is best suited for your project?

At Maker Factory, we advise companies, engineers, designers and hobbyists within prototypes, product development, model building and industrial design.

We offer a wide selection of high-quality 3D printing materials, including PLA, PETG, ABS, TPU and specialty materials, so you get the perfect material tailored to your needs.