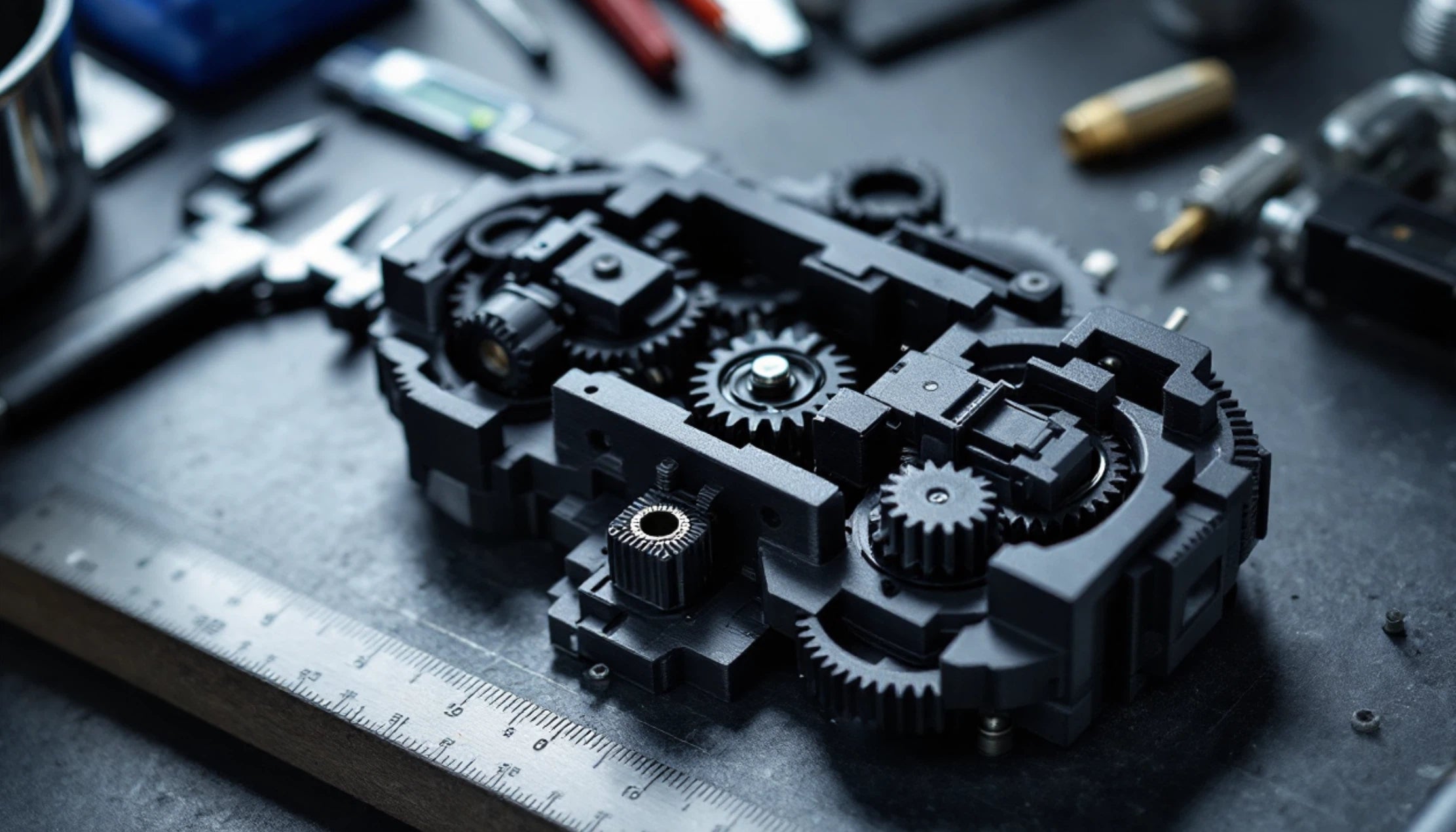

Engineering Resin – Strong & High Precision For Technical Use

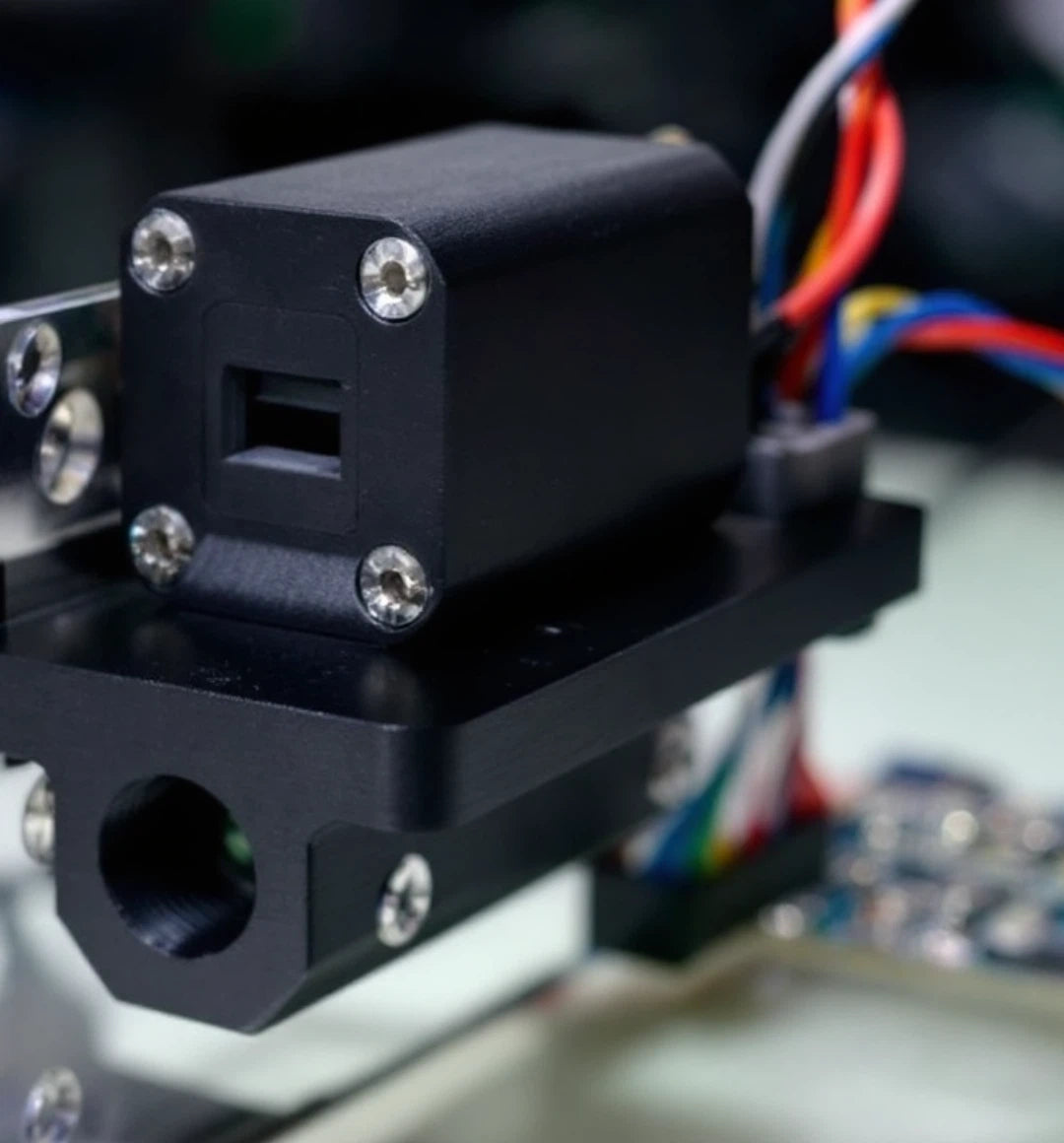

Engineering Resin is a high-performance SLA 3D printing material designed to withstand mechanical stress, chemical attack, and high temperatures. It is often used in engineering, functional prototyping, and technical construction where strength, precision, and durability are essential.

The material combines high tensile strength, toughness and low shrinkage, ensuring that printed parts maintain their dimensions and precision over time. Engineering Resin has improved heat resistance compared to standard resins, making it ideal for machine parts, test components and production tools.

Thanks to its high mechanical strength and chemical resistance, Engineering Resin can be used in demanding industries such as automotive, medical technology and product development, where a reliable and robust material is required.

Properties of Engineering Resin

Engineering Resin is an impact-resistant and heat-resistant material that combines high mechanical strength with excellent precision.

- High strength & low shrinkage – Perfect for precise industrial applications

- Heat resistant up to 90°C – Ideal for technical components

- Chemical resistant – Withstands oil, solvents & cleaning agents

- Excellent mechanical properties – Combines strength & toughness

- Perfect for functional prototypes & production tools

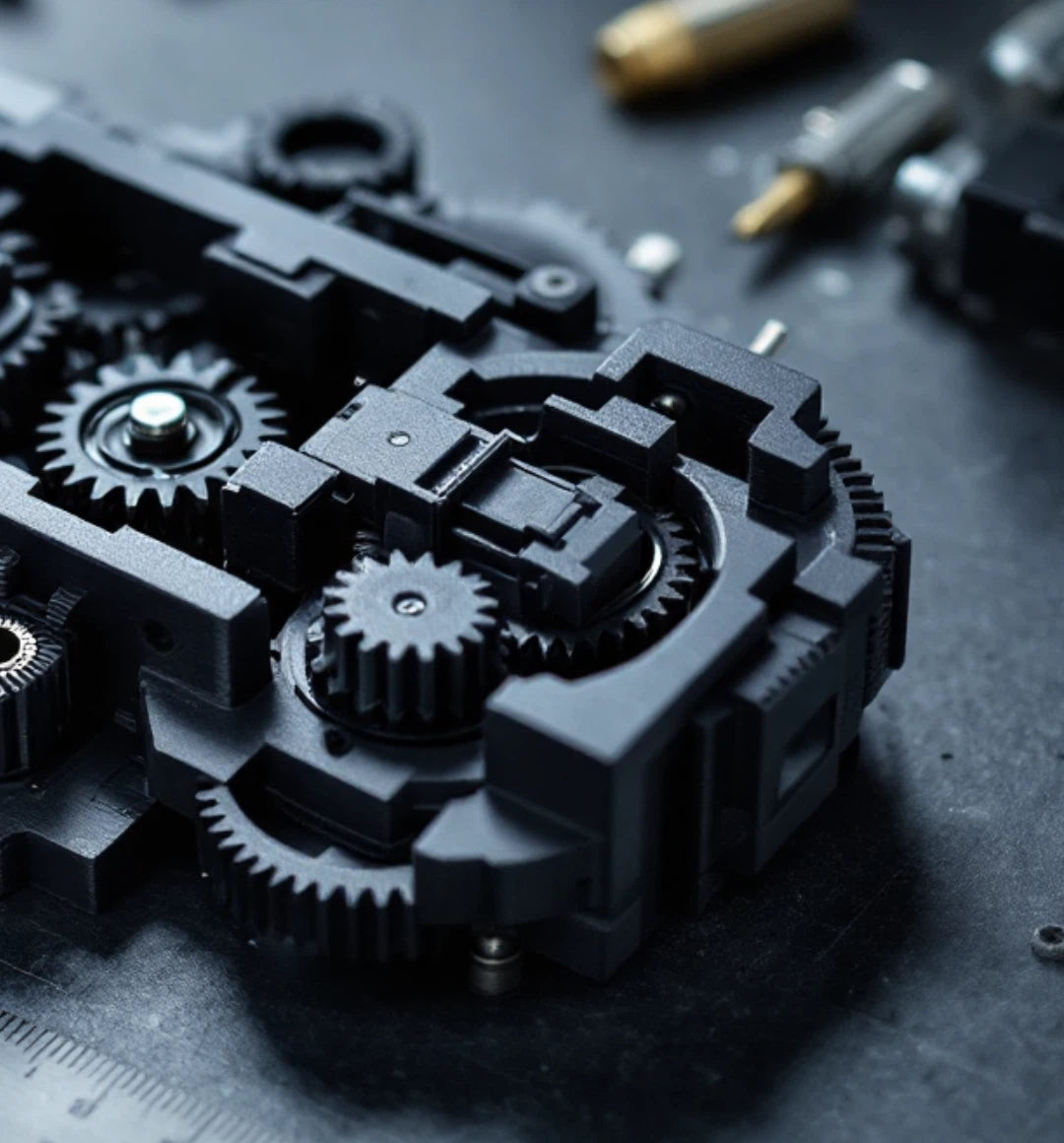

Precision Printing & Technical Strength With Engineering Resin

Engineering Resin is developed for technical applications where strength, precision and heat resistance are important factors. With its high tensile strength and low shrinkage, this material is perfect for mechanical parts that require high precision.

The material can withstand temperatures up to 90°C, making it suitable for machine components, test models and functional prototypes that are exposed to heat and mechanical stress.

Compared to standard resins, Engineering Resin is more durable and chemical resistant, making it ideal for industrial production, automotive solutions and medical technology.

Technical Specification For Engineering Resin

| Egenskab | Engineering Resin |

|---|---|

| Materialetype | Fotopolymer Resin (SLA) |

| Tolerancer | ± 0,05 mm |

| Trækstyrke | 60-80 MPa |

| Elasticitetsmodul | 2,5-3,5 GPa |

| Forlængelse ved brud | 5-15 % |

| Densitet | 1,1-1,2 g/cm³ |

| Hårdhed | 85-90 Shore D |

| Varmebestandighed | Op til 90°C |

| Krympning | Lav |

| Printopløsning | 25-50 mikron |

| Efterbehandling | Slibning, maling, polering, UV-hærdning |

Advantages of Engineering Resin

- High precision & low shrinkage

- Heat resistant up to 90°C

- Perfect for functional prototypes & machine parts

- Resistant to chemicals & mechanical stress

From startups to established companies - we create solutions that suit you

Our customers – Innovation in collaboration

Professional 3D Printing Materials For Precise & Durable Results

Contact Maker Factory – Get the Right 3D Printing Material for Your Project

Are you unsure which 3D printing material is best suited for your project?

At Maker Factory, we advise companies, engineers, designers and hobbyists within prototypes, product development, model building and industrial design.

We offer a wide selection of high-quality 3D printing materials, including PLA, PETG, ABS, TPU and specialty materials, so you get the perfect material tailored to your needs.