3D printing is one of the most revolutionary technologies in modern manufacturing.

It enables rapid prototyping, customized production, and even mass production of complex components. But what are the differences between the various 3D printing technologies—and which one should you choose for your project? In this guide, we’ll walk you through the most popular 3D printing methods, their applications, and their advantages.

What is 3D printing?

3D printing, also known as additive manufacturing, is a process where a physical object is built layer by layer based on a digital model. This technology is widely used in industries such as manufacturing, medicine, automotive, aerospace, and consumer electronics. There are several types of 3D printing technologies, each with unique characteristics and use cases.

The most important 3D printing technologies

1. FDM (Fused Deposition Modeling) – The most common technology

FDM is one of the most widely used 3D printing methods. It works by melting plastic filament and depositing it layer by layer.

Advantages:

-

Affordable and accessible technology

-

Ideal for quick prototypes

-

Wide range of materials (PLA, PETG, ABS, PA, etc.)

Disadvantages:

-

Lower level of detail compared to SLA and SLS

-

Visible layer lines

-

Less mechanical strength than other methods

Applications:

-

Prototypes and concept models

-

Functional parts with moderate precision requirements

-

Hobby projects and education

2. SLA (Stereolithography) – High precision and smooth surfaces

SLA uses a UV laser to cure liquid resin layer by layer. This method delivers highly detailed prints with extremely smooth surfaces.

Advantages:

-

High precision and fine details

-

Smooth surfaces and sharp edges

-

Ideal for small, complex parts

Disadvantages:

-

Materials can be brittle

-

Requires post-processing and UV curing

-

More expensive than FDM

Applications:

-

Medical models

-

Jewelry and dental applications

-

Detailed miniatures and design prototypes

3. SLS (Selective Laser Sintering) – Strong and flexible parts

SLS uses a laser to fuse powdered material layer by layer, producing durable parts without support structures.

Advantages:

-

No supports required

-

Strong and flexible parts

-

Suitable for functional prototypes and end-use products

Disadvantages:

-

Higher cost

-

Requires specialized equipment and post-processing

Applications:

-

Industrial prototypes

-

Medical and automotive components

-

Wear-resistant functional parts

4. MJF (Multi Jet Fusion) – Fast production of functional parts

MJF is a powder-based technology that uses a combination of ink and heat to fuse the material.

Advantages:

-

Fast production speed

-

Strong and durable components

-

Scalable for mass production

Disadvantages:

-

Requires advanced and expensive equipment

-

Fewer material options compared to SLS

Applications:

-

Industrial end-use products

-

Complex functional components

-

Mass production of plastic parts

5. DMLS/SLM (Direct Metal Laser Sintering / Selective Laser Melting) – Metal 3D printing

These technologies use high-powered lasers to fuse metal powder, enabling the creation of complex, high-strength metal parts.

Advantages:

-

Fully dense metal parts with high strength

-

No need for molds or tooling

-

Freedom to design complex geometries

Disadvantages:

-

Very expensive equipment and materials

-

Requires extensive post-processing

Applications:

-

Aerospace and aviation

-

Medical implants

-

High-precision machine parts

How to choose the right 3D printing technology

When selecting a 3D printing method, consider these key factors:

-

Purpose – Is the part a prototype, a functional component, or a visual model?

-

Material requirements – Should it be flexible, durable, heat-resistant, or lightweight?

-

Level of detail – How precise does it need to be?

-

Budget – FDM is typically the most cost-effective, while metal printing is among the most expensive

-

Post-processing needs – Some technologies require more finishing work than others

The future of 3D printing

3D printing continues to evolve and expand across industries and everyday applications. Major trends include:

-

-

New material development – Stronger, lighter, and more eco-friendly materials

-

Faster printing processes – Technologies like MJF and SLA are being optimized for speed

-

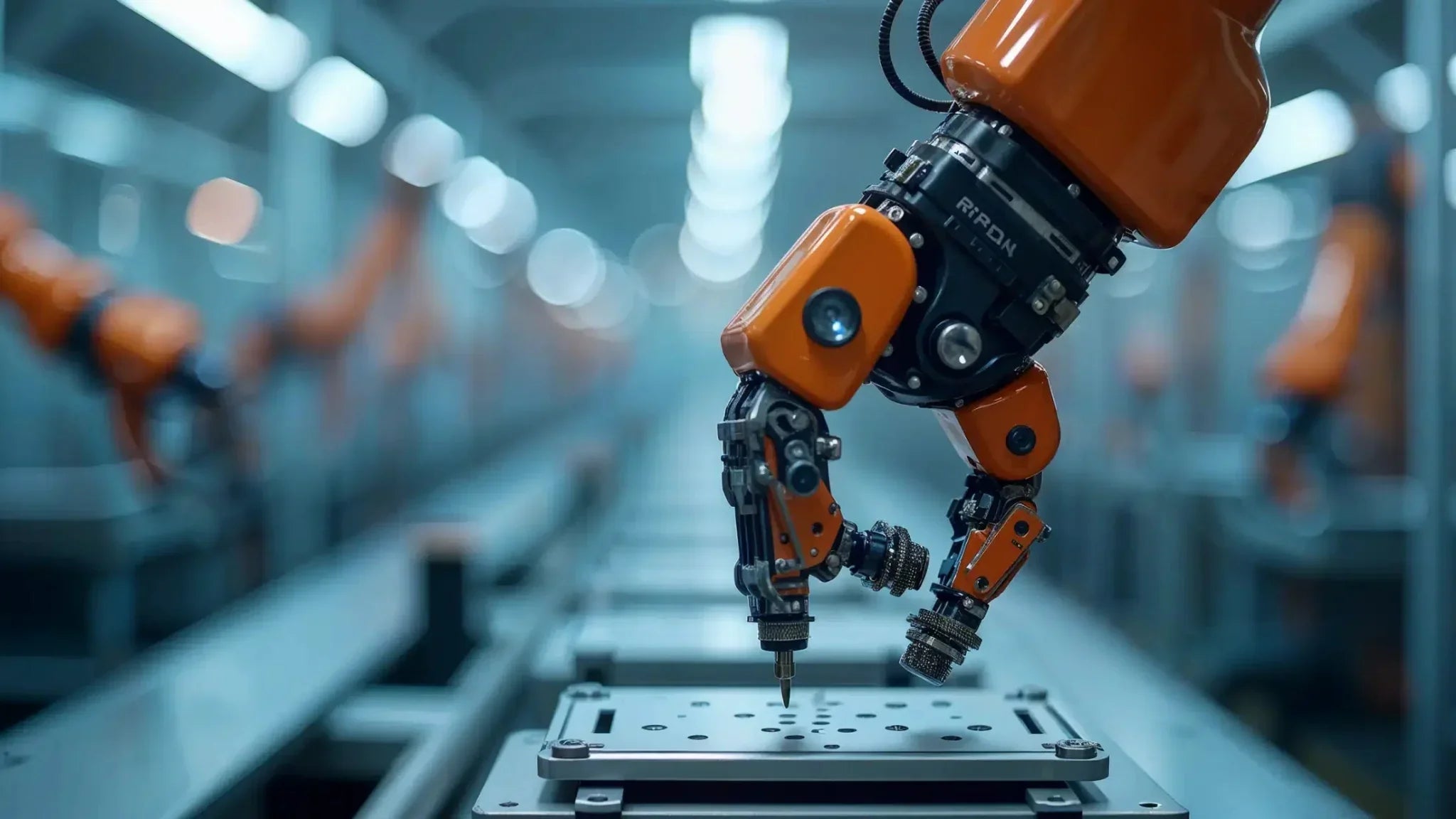

Automation integration – More factories are incorporating 3D printing into production lines

-

Construction-scale printing – Large printers are already being used to build houses and infrastructure

Conclusion

3D printing is a rapidly advancing technology with enormous potential. Choosing the right method for your project helps ensure a more efficient, precise manufacturing process. Whether you need rapid prototypes, functional parts, or full-scale production, there is a 3D printing solution to match your needs.

Want to learn more or need help choosing the right 3D printing technology? Contact Maker Factory today!

-

Share:

How to Optimize Your 3D Designs to Save Time and Money on Printing